Welcome to Saran Brothers

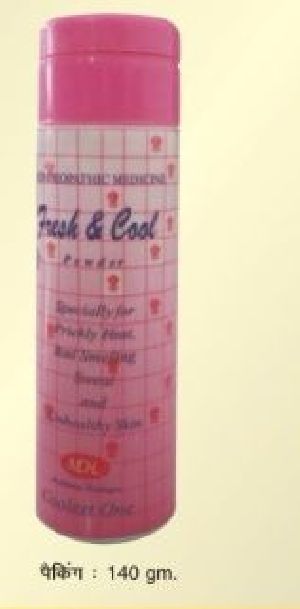

We are oldest manufacturer and supplier of minerals like china clay, talcum powder, dolomite, calcite, bentonite, fire clay, hydrated lime, graphite, precipitated silica, silica gel, activated alumina, molecular sieves, aluminium silicate, tallow,.. Read More

-

Director

Ankit Agarwal

-

Year of Establishment

1935

-

Primary Business

Manufacturer

-

Number of Employees

20 - 50

-

Annual Turnover

Rs. 2.5 to 5 Crore Approx.

-

Market Covered

All Over World.