Listing ID #1419613

Company Information

Ask for more detail from the seller

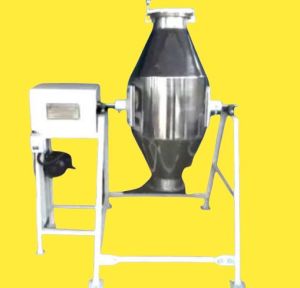

Contact SupplierWe are one of the leading manufacturers and suppliers of Double Cone blenders in Maharashtra. Double blenders are commonly used in the chemical, pharma and food industries, and can effectively mix all densities of dry powders and granules to a fine homogeneous mass, using low shearing force. The slant of the double cone prevents dead spots, which usually occur in other double cone blenders. Made of high quality steel and built in a way so as to enable safe operation, the container rotates at a speed of 8 RPM, and can be customized as per our client’s requirement.

Construction And Operation

Salient Features :

Design is cGMP - Current Good Manufacturing Practices compliance

All Product contact parts AISI 316 & non contact parts AISI 304.

Double Cone shape product container for Ideal dry mixer for lubrication of granules and homogenization mixing of multiple batches in to single batch.

Available Capacity model in octagonal blender 25 kg to 2500 kg batch size..

Enclosed rigid drive with reduction gear box and motor.

"A" type rigid structure of the machine with two sides resting of product container.

Product container having discharge with butterfly valve and man hole.

Charging hole with hinged lid with seal for charging and cleaning.

The product container rotates on sped 8 RPM.

Safety reeling provided for rotating area of product container.

Fixed baffles provided for lumps braking.

Electric controls panel with cycle time.

Safety Features :

Safety reeling with limit switch.

Overload protection and emergency stop.

Optional Features :

Charging Option :

Loading & Unloading by Product container with Jacking trolley.

Vacuum conveying system.

Bin loading by hydraulic hoist.

Rotary Intensifier with AC variable drive.

AC Frequency variable drive for product container.

PLC Controls with HMI touch screen,

Flame proof motor and Push Button station.

Inline milling and loading with vacuum transfer systems.

Applications of Double Blenders : Double Cone blenders can be designed to operate in both batch and continuous modes. Batch type blenders can be built up to capacities of 50 m3. The folloSFEg are the applications of the Blender :

Blending large volumes of dry solids.

Mixing of bulk drugs, chemicals, and cosmetic powders.

Dry Blending of capsule formulations.

Coating solid particles with small amounts of liquids to produce formulations.

Materials commonly blended in the ribbon blender are as follows :

Pesticides and herbicides

Animal feeds

Pet foods

Pharmaceuticals

Fertilizers

Plastic powders

Chemicals

Spice blends

Dietary supplements

Dried food products

|

Model |

Gross Cap. in Liters |

Working Cap. in Liters |

Discharge Ht. in mm |

Discharge Valve |

Overall Dimensions in Length Width Height |

H.P. |

||

|---|---|---|---|---|---|---|---|---|

|

SFE-50 |

150 |

100 |

450 |

150 |

1400 |

800 |

1500 |

2 |

|

SFE-100 |

300 |

200 |

450 |

200 |

1850 |

900 |

1900 |

3 |

|

SFE-150 |

470 |

300 |

450 |

200 |

2000 |

1100 |

2000 |

5 |

|

SFE-200 |

615 |

400 |

450 |

200 |

2100 |

1200 |

2100 |

5 |

|

SFE-250 |

770 |

600 |

450 |

200 |

2200 |

1300 |

2200 |

7.5 |

|

SFE-300 |

1000 |

600 |

450 |

200 |

2300 |

1400 |

2300 |

7.5 |