Listing ID #3465334

Company Information

Ask for more detail from the seller

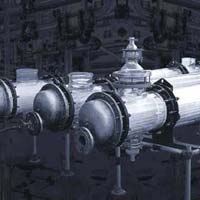

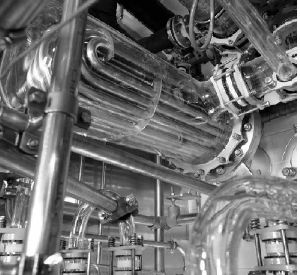

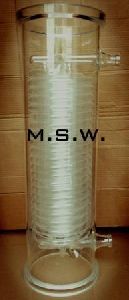

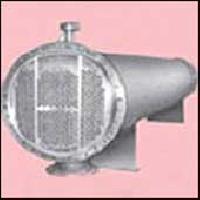

Contact SupplierShell and tube Heat Exchanger are for large heat transfer area, the efficiency of heat transfer and compactness. Shell and Tube Heat Exchanger are widely used as coolers, Condensers, Heaters and Evaporators. Glass Shell and Tube Heat Exchangers are reliable only when leak-free sealing is available between shell & Tube sides. There are two types of Ferrule Sealing in Sigma shell and tube Heat exchangers. Such as:

PTFE Ferrule with Gland Packing.

PTFE Ferrule without Gland packing.

In the case of Ferrule seal with gland packing PTFE ‘O’ Ring & PTFE Rope is used to fill the space between tube and tube sheet and PTFE Ferrule acts as a Gland Follower to make sealing perfect and leak free.

And Ferrule without gland packing is a sealing system where the design of ferrule is such that while tightening. The ferrule gets folded at the seal point of Tube – Sheet in such a way that it does not require ‘O’ Ring or the gland rope and gives as good leak free sealing as in the first case.

This unique ferrule type sealing arrangement permits easy replacement and cleaning of tubes.

Sigma has further improvised on the shell and Tube Evaporators and Re-Boilers with the replacement of Glass Tube by Graphite Tubes and GFT Tube – Sheets. These types are good for high temperature and high-pressure application.