Listing ID #4332477

Company Information

Ask for more detail from the seller

Contact SupplierSmac Epotop Slf Water Absed Epoxy Self Level Flooring, Nano Technology Based Concrete Penetrating sealer, SMAC Elastobond Pu Water Based Anticorrosive Coating, Inorganic Concrete Penetrant and Water Repellant, SMACSIL-IW, SMAC RCCP-200(Oil Base Rust Converetercum Finish Paint).

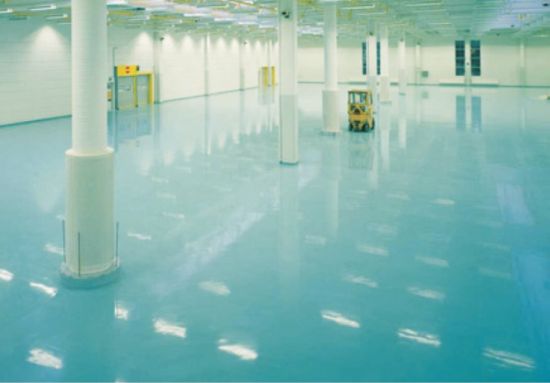

SMAC® EPOTOP SLF is a two component water based Epoxy Self Level Flooring System. It forms a tough, hard, joint-less mirror like finish. It gives a seamless, dustproof and easy to clean hygienic surface which is resistant to many mild chemicals, oils and water.

Advantages :

Application Areas :

Mixing Ratio : 82 part Resin : 18 part Hardener

Method Of Applications : Notched Trowel and spiked roller

Application Procedure :