Welcome to Smitra Enterprises

Manufacturer / Exporter / Supplier / Retailer Of Snap Gauge, Measuring Pins, Industrial Gauges, Measuring Gauges, Taper Plug Gauge, Metric Taper Gauge

Welcome to Smitra Enterprises

Manufacturer / Exporter / Supplier / Retailer Of Snap Gauge, Measuring Pins, Industrial Gauges, Measuring Gauges, Taper Plug Gauge, Metric Taper Gauge

The ISO Taper Gauges, both Plug and Ring type are made of superior quality high Carbon Chrome alloy Steel. Heat Treated and hardened to 58-60 HRC, to provide a high degree of wear resistance. Fine lapped to get maximum seating and surface finish. The Taper Gauges are rough ground and kept for a long period of time before finishing is given; this is done to prevent any distortions and ensure stability through their use.

he Morse Taper Gauges, both Plug and Ring type are made of superior quality high Carbon Chrome alloy Steel. Heat treated and , hardened to 58-60 HRC, to provide a high degree of wear resistance. Fine lapped to get maximum seating and surface finish. Rough ground and kept for a long period of time before finishing is given; this is done to prevent any distortions and ensure stability through their use. Common Uses

The Inspection Mandrels are made of hardened and stabilized steel. For easy usage and accuracy the Mandrels are provided with properly ground and lapped centers, recessed at both ends for protection from damage. The 4 reference lines ( r ) are spaced 90 degree apart on the mandrel cycliner (ref. 1, 2, 3, 4 in fig 2) for use in testing machines. In Morse and Metric Tapers, the Mandrels are self holding in the socket (ref. fig. 2 ). A threaded hole is provided to fit a nut to extract the Mandrel from the socket. In Steel or ISO Tapers, a tapped hole is provided for fixing the mandrel with a threaded retaining pin (ref. fig.3).To avoid Mandrel cylinder surface from being ' turned ' (by grinding) the Mandrel has an extension ( ref. P in fig.4) 14 to 32 mm in length and of slightly less diameter than of the Mandrel cylinder.

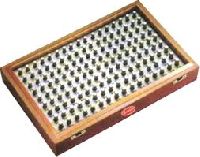

The Cylindrical Measuring Pins are made of superior quality high Carbon Chrome alloy steel, hardened to 58-60 HRC, to provide a high degree of wear resistance. The Measuring Pins are made of high accuracy and have a fine surface finish. Common Uses The Measuring Pins are for checking bores, tapers, distances, thread teeth, and for general gauging purposes. Scope of Supply The Smitra Measuring Pins are manufatured as per IS - 11103 - 1984, with or without aluminium knobs. The measuring pins are supplied in Gauge box for safe keeping.

The Snap Gauges are made of superior quality high Carbon Chrome alloy Steel. Heat treated and hardened to 58-60 HRC, to provide a high degree of wear resistance. The Snap Gauges are manufactured to close tolerance such as to ensure optimum life of the Gauges yet offer minimal manufacturing tolerance. The Gauges are properly stabilized to prevent dimensional inaccuracies and ensure stability throughout their use. Common Uses

The Inspection Mandrels are made of hardened and stabilized steel. For easy usage and accuracy the Mandrels are provided with properly ground and lapped centers, recessed at both ends for protection from damage. The 4 reference lines ( r ) are spaced 90 degree apart on the mandrel cycliner (ref. 1, 2, 3, 4 in fig 2) for use in testing machines. In Morse and Metric Tapers, the Mandrels are self holding in the socket (ref. fig. 2 ). A threaded hole is provided to fit a nut to extract the Mandrel from the socket. In Steel or ISO Tapers, a tapped hole is provided for fixing the mandrel with a threaded retaining pin (ref. fig.3).To avoid Mandrel cylinder surface from being ' turned ' (by grinding) the Mandrel has an extension ( ref. P in fig.4) 14 to 32 mm in length and of slightly less diameter than of the Mandrel cylinder.

Share your thoughts with other customers for Smitra Enterprises

Add Review