Listing ID #3811370

Company Information

Ask for more detail from the seller

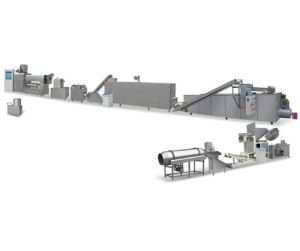

Contact SupplierThis machine is used for producing the non-woven fabrics film automatically. Spinning die-head adopts design optimization of flow models of coat-hanger type, equality distribution of melt,balance pressure, Non-broken or combine fibre,no holes,no blind angle,and fastly Color transition.Rolling mill adopts DC motor universal joint transfer, roller adopts technology of Ultra Laser Drilling to ensure the same of the temperature, no Hair-in-filling.The equipment adopts cutting on line, automatic low winding technology, in order to Serve Resource, and improve the production efficiency.

1. Application:

This Produce line is filament polypropylene fiber spunbonded nonwoven fabrics equipment. Its raw material is polypropylene (PP), take the principle of spinning man-made fibers, during polymer filature, continuous filament is extended into fiber net, which is finished by mechanical hot pressing, The machine assembly we adopt is now advanced veneer integer slot air flow draw technology, the whole process from material feeding to cloth output is automatic control, short production flow, high working efficiency.

The nonwoven fabrics we produce has high strength, good softness, innocuity, bacterium-proof, corrosion resistance, high-level draw strength and elongation rate, They are widely used for dress, decoration materials, medical sanitation materials, daily life products and in the industrials, agriculture fields. In additional, this production line can produce nonwoven fabrics of different color, different grams, different lines according to users’ requirements.

Lines on nonwoven fabrics : dots, cross line, straight lines, weight:10-200g/m2

Raw material : Polypropylene chips(melt index:20-40g/10min, melt point:166 degree centigrade,

ash content: < 0.15-0.25%)

Feeding(suction, dosing and mixing) -->Melt and extruding(with recycle extruder)-->Filtering -->

Metering --> Spinning --> Quenching --> Air drawing --> Forming --> Calendering --> Winding --> Slitting

--> Product