Listing ID #3929776

Company Information

Ask for more detail from the seller

Contact SupplierThis can also be interlocked to check which process or machine is demanding the material. This requires an electronic eye coupled with pneumatic system.

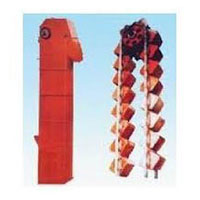

The pendulum bucket elevator is made from free swinging buckets which are always upright. This gives the possibility for numerous line configurations, up or up and down and numerous discharges at any position