Listing ID #2564500

Company Information

Ask for more detail from the seller

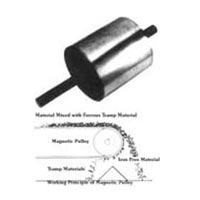

Contact SupplierOur Magnetic Pulleys are suitable for removing ferrous impurities from granulate or powdered material such as waste, coal, sand etc. These Magnetic Pulleys are manufactured from stainless steel, and has a design that ensures continuous magnetism doe continuous operation. Our range of Magnetic Pulleys is used in various industries such as chemical, rubber, foundry, paper and pulp, glass etc.

Design Advantage

Star Trace Magnetic head pulleys are built using our exclusive flux control magnetic circuit. This design ensures continuous magnetism around the entire circumference of the pulley-no dead spots. For less critical applications, a conventional magnetic circuit design is also offered.

Types of Strength

| (A) PULLEY DIAMETER in mm | (B) OVERALL FACE WIDTH in mm | (C) BELT WIDTH in mm | (D) KEYWAY LENGTH in mm | (E) EXTENSION LENGTH in mm | (F) DRIVE EXTENSION LENGTH in mm | (G) SHAFT DIAMETER in mm | KEYWAY SIZE in mm | APPROX WEIGHT in kg |

|---|---|---|---|---|---|---|---|---|

| 200 | 250 | 200 | 75 | 150 | 230 | 35 | 10 X 5 | 30 |

| 300 | 250 | 75 | 150 | 230 | 35 | 10 X 5 | 34 | |

| 350 | 300 | 75 | 150 | 230 | 35 | 10 X 5 | 45 | |

| 400 | 350 | 75 | 150 | 230 | 35 | 10 X 5 | 50 | |

| 450 | 400 | 75 | 150 | 230 | 35 | 10 X 5 | 56 | |

| 500 | 450 | 75 | 150 | 230 | 35 | 10 X 5 | 59 | |

| 550 | 500 | 75 | 150 | 230 | 35 | 10 X 5 | 63 | |

| 650 | 600 | 75 | 150 | 230 | 35 | 10 X 5 | 70 | |

| 800 | 750 | 75 | 150 | 230 | 35 | 10 X 5 | 92 | |

| 950 | 900 | 75 | 150 | 230 | 35 | 10 X 5 | 104 | |

| 300 | 350 | 300 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 104 |

| 400 | 350 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 117 | |

| 450 | 400 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 126 | |

| 500 | 450 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 153 | |

| 550 | 500 | 100 | 230 | 330 | 50 | 12.5 X 6.5 | 164 | |

| 650 | 600 | 125 | 230 | 330 | 70 | 16 X 8 | 189 | |

| 800 | 750 | 125 | 230 | 350 | 70 | 16 X 8 | 230 | |

| 950 | 900 | 125 | 230 | 350 | 70 | 16 X 8 | 272 | |

| 1100 | 1050 | 125 | 250 | 380 | 70 | 16 X 8 | 313 | |

| 1250 | 1200 | 125 | 250 | 380 | 70 | 16 X 8 | 358 | |

| 380 | 350 | 300 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 137 |

| 400 | 350 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 167 | |

| 450 | 400 | 125 | 230 | 350 | 60 | 16 X 8 | 169 | |

| 500 | 450 | 125 | 230 | 350 | 60 | 16 X 8 | 209 | |

| 550 | 500 | 125 | 250 | 380 | 60 | 16 X 8 | 223 | |

| 650 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 259 | |

| 800 | 750 | 150 | 280 | 430 | 75 | 19 X 10 | 335 | |

| 950 | 900 | 150 | 280 | 430 | 75 | 19 X 10 | 394 | |

| 1100 | 1050 | 150 | 300 | 450 | 75 | 19 X 10 | 457 | |

| 1250 | 1200 | 150 | 300 | 450 | 75 | 19 X 10 | 518 | |

| 450 | 350 | 300 | 125 | 230 | 350 | 60 | 16 X 8 | 178 |

| 400 | 350 | 125 | 230 | 350 | 60 | 16 X 8 | 203 | |

| 450 | 400 | 125 | 230 | 350 | 60 | 16 X 8 | 234 | |

| 500 | 450 | 125 | 230 | 350 | 60 | 16 X 8 | 297 | |

| 550 | 500 | 125 | 250 | 380 | 75 | 19 X 10 | 306 | |

| 650 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 367 | |

| 800 | 750 | 150 | 280 | 430 | 75 | 19 X 10 | 468 | |

| 950 | 900 | 150 | 280 | 430 | 75 | 19 X 10 | 574 | |

| 1100 | 1050 | 150 | 300 | 450 | 75 | 19 X 10 | 673 | |

| 1250 | 1200 | 150 | 300 | 450 | 75 | 19 X 10 | 772 | |

| 500 | 400 | 350 | 125 | 230 | 350 | 60 | 16 X 8 | 248 |

| 450 | 400 | 125 | 230 | 350 | 60 | 16 X 8 | 275 | |

| 500 | 450 | 125 | 250 | 380 | 60 | 16 X 8 | 311 | |

| 550 | 500 | 125 | 250 | 380 | 60 | 16 X 8 | 349 | |

| 660 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 414 | |

| 810 | 750 | 150 | 280 | 430 | 75 | 19 X 10 | 554 | |

| 960 | 900 | 150 | 280 | 430 | 75 | 19 X 10 | 671 | |

| 1110 | 1050 | 150 | 300 | 450 | 75 | 19 X 10 | 794 | |

| 1270 | 1220 | 150 | 300 | 450 | 75 | 19 X 10 | 907 | |

| 1420 | 1370 | 175 | 300 | 480 | 75 | 19 X 10 | 1037 | |

| 1570 | 1520 | 175 | 300 | 480 | 75 | 19 X 10 | 1175 | |

| 600 | 400 | 350 | 125 | 230 | 350 | 75 | 19 X 10 | 342 |

| 450 | 400 | 125 | 230 | 350 | 75 | 19 X 10 | 362 | |

| 500 | 450 | 125 | 250 | 380 | 75 | 19 X 10 | 369 | |

| 550 | 500 | 125 | 250 | 380 | 75 | 19 X 10 | 432 | |

| 660 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 527 | |

| 810 | 750 | 150 | 330 | 480 | 85 | 22 X 11 | 693 | |

| 960 | 900 | 150 | 330 | 480 | 85 | 22 X 11 | 815 | |

| 1110 | 1050 | 175 | 350 | 530 | 100 | 25 X 12.5 | 929 | |

| 1270 | 1220 | 175 | 350 | 530 | 100 | 25 X 12.5 | 1040 | |

| 1420 | 1370 | 200 | 380 | 580 | 100 | 25 X 12.5 | 1217 | |

| 1570 | 1520 | 200 | 400 | 600 | 100 | 25 X 12.5 | 1357 | |

| 750 | 500 | 450 | 125 | 350 | 500 | 100 | 25 X 12.5 | 677 |

| 550 | 500 | 125 | 350 | 530 | 100 | 25 X 12.5 | 711 | |

| 660 | 600 | 125 | 350 | 530 | 100 | 25 X 12.5 | 855 | |

| 810 | 750 | 150 | 400 | 580 | 110 | 25 X 12.5 | 1085 | |

| 960 | 900 | 150 | 400 | 580 | 110 | 25 X 12.5 | 1278 | |

| 1110 | 1050 | 175 | 450 | 630 | 125 | 32 X 16 | 1530 | |

| 1270 | 1220 | 175 | 450 | 630 | 125 | 32 X 16 | 1737 | |

| 1420 | 1370 | 230 | 500 | 760 | 140 | 32 X 16 | 1937 | |

| 1570 | 1520 | 230 | 480 | 730 | 140 | 32 X 16 | 2167 | |

| 900 | 500 | 450 | 150 | 300 | 450 | 100 | 25 X 12.5 | 997 |

| 550 | 500 | 150 | 300 | 450 | 100 | 25 X 12.5 | 1040 | |

| 660 | 600 | 175 | 300 | 530 | 110 | 25 X 12.5 | 1217 | |

| 810 | 750 | 175 | 300 | 530 | 110 | 25 X 12.5 | 1494 | |

| 960 | 900 | 200 | 350 | 560 | 125 | 32 X 16 | 1814 | |

| 1110 | 1050 | 200 | 350 | 560 | 125 | 32 X 16 | 2093 | |

| 1270 | 1220 | 230 | 380 | 660 | 140 | 32 X 16 | 2408 | |

| 1420 | 1370 | 280 | 380 | 710 | 150 | 38 X 19 | 2723 | |

| 1570 | 1520 | 330 | 430 | 810 | 175 | 38 X 19 | 2993 |