Listing ID #3903153

Company Information

Ask for more detail from the seller

Contact SupplierIt’s not just about saving fuel in a boiler, even your process may be such that it includes furnaces, kilns where a large proportion of heat after combustion of fuel gets wasted as a dry flue gas loss.

Though in this case, you are not using extra fuel in your equipment still there are a huge amount of flue gas losses.

This heat can be utilized somewhere in a process where you are currently using fuel to generate heat either to produce steam or even for local heating of water or air or any other fluids.

Remember energy is precious, even small saving in energy cost will save you a lot of money which can usually be seen over a period of 1 year.

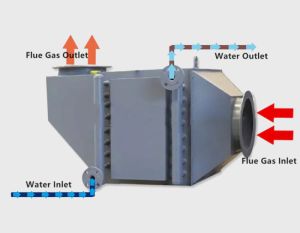

Due to this, we provide novel products like Wastetherm, the Waste Heat Recovery Boilers (WHRB). As the name suggests, the heat going waste from the process like flue gases of Diesel Generator sets is utilized in these boilers to generate hot water or steam.

Since no fuel is fired, whatever heat we recover in the boiler is free of cost.

Waste Heat Recovery boilers are designed to recover heat from waste flue gases from DG exhaust, Furnace exhaust, Kiln exhaust, incinerator exhaust etc. to produce steam or hot water based on the application requirements of the plant.

There are 4 basic requirements or inputs for calculating your waste heat from the source. These are:-

The amount of steam generators or Steam Boilers of heat transfer is controlled by the quantity of heat available in the flue gases. Wastetherm can be fire tube or water tube type as per the design requirements.

Tailor-made solutions are offered based on specific requirements of customers and the Wastetherm boiler design is integrated into the system requirements. Since these boilers operate on waste heat, there are no fuel bills to operate these and hence they offer the very handsome payback of investments.

Wastetherm can be either smoke tube design or water tube design. Depending upon the amount of waste heat available and the process where you want to utilize this waste heat say for an instance for producing steam, the required capacity and pressure of steam will help to determine the design of a waste heat boiler.

Waste Heat Recovery Boilers (WHRB)Benefits :