Welcome to Chapel Hill Mfg.

Manufacturer / Exporter / Supplier Of BGK Shrinking Yarn, Blue Lightning, Gravure Cover, Blue Boi, Slip Tube

-

Year of Establishment

1962

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to Chapel Hill Mfg.

Manufacturer / Exporter / Supplier Of BGK Shrinking Yarn, Blue Lightning, Gravure Cover, Blue Boi, Slip Tube

Year of Establishment

1962

Primary Business

Supplier

Number of Employees

10-49

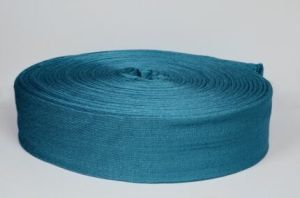

BGK is knit with moisture activated, shrinking yarn. In order to avoid premature shrinkage, store in a cool, dry place. Reseal the plastic storage bag securely after each use. Cut cover about 12” longer than the roller. Allow extra material when using cable ties to secure to roller coreshaft. Simply slide the cover over the roller. Wet only the middle half of the cover with hot water 120°F (50°C) maximum in one minute. The purpose of pre-wetting just the center area of the roller is to allow some lateral shrinkage to take place before the ends are secured. This will reduce the possibility of the cover shrinking off the roller. IMPORTANT: Do not wet the cover any closer than 6″ (152.4mm) of the roller ends. The ends of the cover can be sewn or wrapped tightly with string or secured with nylon cable ties. If sewing, make close stitches approximately 14″ (6.35mm) apart. Now saturate the entire cover with warm to hot water for about one minute. (Note: Proper water temperature is required to assure complete shrinkage) Mount the roller(s) on the press. Adjust the cover-to-plate pressure according to the press manufacturer’s specifications. Note that BGK absorbs and retains more fountain solution than cotton dampening materials and may require less pressure andor a lower water transfer setting than you are accustomed to using.Shrink to fit. Lint free, pattern free, ink resistant Densely knit cover, highly absorbent, excellent water control No creeping, twisting, or “walking” off the roller, even at high speeds No solvents, manual scrubbing, or specialized cleaning machinery is required, just hot waterBetter print quality. Increases productivity with uninterrupted printing. Lasting up to 5 time longer than cotton. Save time: easy to install on the roller and fast start-up. Reduce your installation time, less downtime. Save money: go from black ink to yellow ink, or any other light color, without having to change covers.

All the covers should be LOOPS OUT! Cut the cover about 15-20% longer than the roller. Allow extra material when using cable ties to secure to roller coreshaft. At one end, turn in approximately 4-5 inches of the coverMount the end folded inward of the cover onto the roller then pull it down to cover the roller completely. When the cover is mounted with loops out, thoroughly saturate the entire roller with water 120oF (50oC) in 2-3 minutes to activate shrinkage. Use your hands to squeeze off the excess water. Fasten both ends of the cover securely by nylon cable ties or hand sewn.Shrink to fit Lint free, pattern free Ink repellent, easy to clean up Multi-directional adjustment to the roller More absorbent, specially treated fibers for optimal water absorption Uniform water transferLasts longer than cotton (4 to 10 times longer) Reduces your installation time, less downtime Easy to install on the roller and “Ready to go!”

All the covers should be LOOPS OUT! Cut the cover about 15-20% longer than the roller. Allow extra material when using cable ties to secure to roller coreshaft. At one end, turn in approximately 4-5 inches of the cover.Mount the end folded inward of the cover onto the roller then pull it down to cover the roller completely. When the cover is mounted with loops out, fasten both ends of the cover securely by nylon cable ties or hand sewn. Thoroughly saturate the entire roller with water 120oF (50oC) in 2-3 minutes to activate shrinkage. Use your hands to squeeze off the excess water.Shrink to fit, lint free, pattern free Ink repellent, easy to clean up Superior water absorption under stress and won’t mat or pack down.Lasts longer than cotton (4 to 10 times longer) Reduce your installation time, less downtime Easily install on the roller and “Ready to go!”

All the covers should be LOOPS OUT! Cut the cover about 15-20% longer than the roller. Allow extra material when using cable ties to secure to roller coreshaft. At one end, turn in approximately 4-5 inches of the cover.Mount the end folded inward of the cover onto the roller then pull it down to cover the roller completely. When the cover is mounted with loops out, thoroughly saturate the entire roller with water 120oF (50oC) in 2-3 minutes to activate shrinkage. Use your hands to squeeze off the excess water. Fasten both ends of the cover securely by nylon cable ties or hand sewn.Lasts longer than cotton (4 to 10 times) Easy to install and “Ready to Go!” Reduces the installation time, less downtime.Shrink to fit Lint free, pattern free Ink repellent, easy to clean up Multidirectional adjustment to the roller More absorbent, specially treated fibers for optimal water absorption Uniform water transfer

Chapel Hill tubes are made from strong rigid plastic. They’re designed to make the installation of dampening covers easier on the press roller. Simply slide the cover over the tube, then slide the tube over your roller. Now transfer the cover onto your roller as you remove the tube.

Share your thoughts with other customers for Chapel Hill Mfg.

Add Review