Welcome to Commercial Dehydrator Systems

Manufacturer / Exporter / Supplier Of Harvest Saver Tray Dryer, Klamath K2 Tray Dryer, McKenzie Tray Dryer, Columbia Tunnel Dryer, Belt Dryers, Bin Dryers

Welcome to Commercial Dehydrator Systems

Manufacturer / Exporter / Supplier Of Harvest Saver Tray Dryer, Klamath K2 Tray Dryer, McKenzie Tray Dryer, Columbia Tunnel Dryer, Belt Dryers, Bin Dryers

Commercial Dehydrator Systems continuous flow belt dryers are the most uniform and consistent dehydration systems available today. Ruggedly constructed of durable, sanitary stainless steel, the Commercial Dehydrator Systems belt dryers are specifically tailored for just one product, yours. Energy efficient modular design produces optimum ease in clean ability. Whatever the product, these state of the art dryers provide maximum control of processing parameters. Fully insulated with fiberglass insulation and finished in industrial enamel, the Commercial Dehydrator Systems belt dryers are equipped with UL compliant gas trains and systems. Temperature control, balanced air flow and relative humidity are all individually controlled in each zone. A clean-in-place system for belt cleanliness is also available. The variable speed belt, motor controls, starters and safety alarms are all handled from the control panel, providing additional product drying flexibility. Belt dryers provide reduced dwell times, ensuring your product is uniformly and carefully dried. Energy efficient layout and low labor requirement maximizes investment payback. Sanitary construction and consistent high quality make the Commercial Dehydrator Systems continuous flow belt dryers far ahead of the competition.

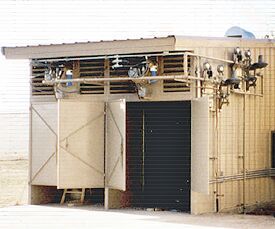

The MBD-5 is a commercial quality bin dryer used to dry products requiring long dwell times. The advanced design of Commercial Dehydrator Systems Bin Dryers maximizes production and minimizes down time, by affording discreet control over the process air temperature, air velocity, and humidity, not as a group, but to each individual bin. The results are spectacular, often five bins do the work of eight standard units. Dehydration is virtually continuous, with three bins running, while the fourth bin is filling, and the fifth bin is discharging dried product. The MBD-5 is shipped prefabricated from the factory and requires little in the way of assembly on site. Constructed in blocks of five bins, from mild steel and finished in industrial enamel, each bin has been designed to function independently. Horizontal in-feed conveyors serve each block of dryers, and two blocks of five can discharge into one horizontal discharge conveyor. Both sets of conveyors are included. Commercial Dehydrator Systems Bin Dryers have set a new standard in performance, not only in production, but in the quality dehydration possible by discreet control of individual bins.

Share your thoughts with other customers for Commercial Dehydrator Systems

Add Review