Welcome to Dixon Automatic Tool, Inc.

Manufacturer / Exporter / Supplier Of Nut Driving Head, Part Placing Head, High Torque Screw, Screwdriving Work-Cell

-

Year of Establishment

1946

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Dixon Automatic Tool, Inc.

Manufacturer / Exporter / Supplier Of Nut Driving Head, Part Placing Head, High Torque Screw, Screwdriving Work-Cell

Year of Establishment

1946

Primary Business

Supplier

Number of Employees

50-99

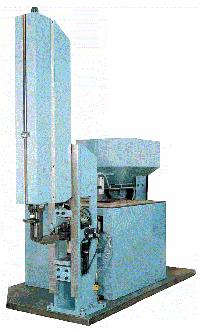

The Model 3120 Screwdriving Cell is an ideal work station for semi-automatic assembly operations. This cell requires an operator to manually place the workpiece into a work holding fixture and to initiate cycle. A magnatorque rotary servo motor is used to rotate the fixture and workpiece components. This Cell can be fitted with several different screwdriver heads if required for specific driving requirements. The size of the vibratory feeder bowl is determined by size of the fastener. Appropriate operator guards such as light curtains sensors are selected because of the manual placement and removal of workpieces. REQUEST A QUOTE DOWNLOAD PRODUCT PDF

AP-100 Series Part Placing Head – Part Placers are used for various applications and the type of feeding system required is determined by the part geometry and placement of the part. AP-100 head is capable of placement rates of up to 80 per minute which sets it apart from other basic pick and place units. The AP-100 head has a placing cylinder that is cushioned at both ends, with strokes from 2-5 ins. and pressing forces between 40 and 175 pounds. The hardened jaws are custom machined to grip and align each piecepart and then mechanically opened using opening cam assembly as the piecepart engages the workpiece. Each piecepart is properly placed into the workpiece using verification sensing. Control switches also provide for the driving head to return and other auxiliary functions as may be required.

SD-100 Series ScrewNut Driving Head – Standard features include a pneumatic motor with driving or reversible rotations, and selected for a range of speeds and torque capacities. Optional D.C. and servo motors are available. Pneumatic control valve with DIN connectors. Control switches also provide for the driving head to return and other auxiliary functions as may be required. The basic driving function starts the driving spindle to advance together until the fastener, held in the placement jaws, spindle and placement jaws advance together until the fastener engages the workpiece. The placement jaws are then forced opened by a cam as the driving spindle completes the fastener’s insertion. Note: When vacuum is employed, the placement jaws are opened before the fastener is driven into the workpiece.

Share your thoughts with other customers for Dixon Automatic Tool, Inc.

Add Review