Welcome to Epsilon Industries, Inc.

Manufacturer / Exporter / Supplier Of Mold Fabrication Tooling, Plastic Part Production, CAD Design, Rapid Prototyping

-

Year of Establishment

1983

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to Epsilon Industries, Inc.

Manufacturer / Exporter / Supplier Of Mold Fabrication Tooling, Plastic Part Production, CAD Design, Rapid Prototyping

Year of Establishment

1983

Primary Business

Supplier

Number of Employees

10-49

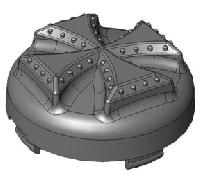

Injection molded plastic parts are made by shooting molten plastic into cavities-which are the negative shape of the part; letting the plastic cool; then opening the two halves of the mold and ejecting the finished plastic part. When a small number of parts are desired, the tooling represents the bulk of the cost, but when a large number of parts are created, since the tooling is a one-time cost and is averaged over then number of parts, the relative cost of tooling shrinks dramatically to where – in extremely large quantities – the cost of tooling is reduced to practically zero.

Your steel or aluminum mold will make as many or as few parts as you need. We typically shoot parts in the most common thermoplastics including ABS, nylon, polypropylene, HIPS (High Impact Polystyrene), polycarbonate, and TPE (synthetic rubber), but we are willing to work with nearly any material you specify. Pricing is set per part and depends on the material, the complexity of the part, the volume of the part, and the quantity of parts ordered. Epsilon has very competitive per part pricing – both for the low-volume, short-run orders and the high-volume, long-run orders. Epsilon can create an injection mold to your specifications, or use an existing mold. When the production run is complete, we will either ship your mold with your order or retain it for future orders – whichever is your preference.

Using a 3D CAD model we can print your part out in the actual size and shape it was designed. We achieve this is using FDM (Fused Deposition Modeling). The 3D printer starts at a bottom plane and works its way up layer-by-layer depositing either a support structure or a special plastic until the entire model is complete. The support structure is then washed away and the remaining part is an exact-scale prototype of your part. Rapid prototypes are useful as a way to double-check a design — makes sure everything fits and functions as it was designed. It also can act as a design aid as you may use the model to check the aesthetics or function in an iterative design flow. There are some minor drawbacks to the prototypes. Since the layers are around .010″ thick, the parts tend to have a stepped texture – particularly along curved surfaces. This can be minimized through post-process techniques such as sanding and filling, but for most applications it is an extremely minor issue. Also at issue is the relative frailty of the parts. Being used to injection molded thermoplastics, most people are surprised when they find they can break the prototypes apart with their hands. Unfortunately the layering process does not allow for the same internal bonding to occur as it does in traditional methods, but a little care – especially with skinny features – will ensure that you prototype remains intact.

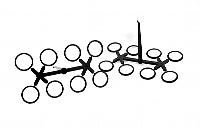

Minimal technical detail is necessary to develop a working 3D CAD model; if all you have is a drawing on a napkin, we have worked with less! We can reverse engineer your part or prototype and develop an exact CAD model for production. (Including 2D to 3D from existing plansdrawings) Our CAD designers work with you throughout the design process to develop exactly the product you want. Current technology allows us to e-mail a viewable 3D model to you at various points in the design process so you know exactly the status and direction of your project. (Example) With lead times around 1-2 weeks for CAD work, we can get your project jump-started quickly and provide a quick turnaround. Being wholly based in the USA, Epsilon reduces the communication difficulties and time lags that often plague companies operating overseas. From This: To This: ↑ A fully defined 3D CAD model. DATA & OUTPUT CAPABILITIES Our CAD designers use Solidworks to output 3D models in a variety of standard formats, including IGES, STEP, STL, Parasolid, and ACIS, as well as the Solidworks native format. These formats are near universal for any rapid prototyping, mold-making or further CAD development necessary.

Share your thoughts with other customers for Epsilon Industries, Inc.

Add Review