Welcome to Faspro Technologies, Inc

Manufacturer / Exporter / Supplier Of Spring Contacts, Metal Forming Services, Photochemical Etching, Medical Devices

-

Year of Establishment

1995

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Faspro Technologies, Inc

Manufacturer / Exporter / Supplier Of Spring Contacts, Metal Forming Services, Photochemical Etching, Medical Devices

Year of Establishment

1995

Primary Business

Supplier

Number of Employees

50-99

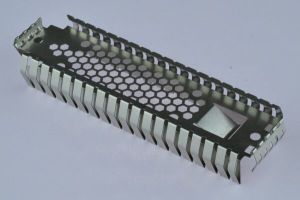

New product development for industry-leading electronic device manufacturers involves balancing the competing interests of design, schedule and cost. Most OEM device manufacturers rely on custom metal fabrication to ensure effective product design, improved efficiency, and maximum profitability. Sometimes the right partner can make the difference in launching a new product that meets or exceeds expectations. As your source for custom metal fabrication, Faspro Technologies brings expertise in forming and drawing of thin gauge metal parts to support prototype and pre-production manufacturing. Providing quick turnaround and cost effective processes that result in high-quality product allow the OEM to properly evaluate new products and make changes before committing to expensive and long lead production tooling.

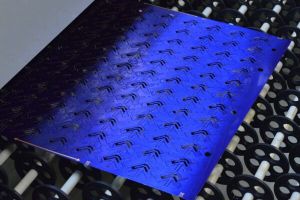

Photochemical machining (PCM), which is also called photochemical milling or photo etching, is a process that uses chemicals to fabricate sheet metal components. A photoresist is used to mask the metal while chemical etchants corrosively machine the untreated areas. At Faspro we use photochemical milling to produce very complex parts with fine detail. The accuracy of the process and its low cost make it attractive for prototype and short run production.

Electromagnetic interference (EMI) can affect a hospital’s electronic equipment when an emitting device is powerful enough and close enough to cause partial or complete failure of the equipment or its sub systems. When a transmitting device gets closer to susceptible electronic equipment, the chance of interference grows. Likewise, as the power of an RF transmitter increases, interference is more likely to occur. Of course, failure of critical electronic medical equipment can be life threatening and should be prevented whenever possible.

Spring contacts (sometimes called shield fingers, grounding springs or universal ground contacts) are used in virtually every small printed circuit board application. A spring contact can be described as a single contact, surface mountable, internal connector. They feature an electrical connection and protection from EMI noise and static between a PCB and other electronic components, for example a secondary PCB, internal antenna, microphone or speaker. Key features and applications of spring contacts include: Designed for conductivity and grounding between an internal component and a PCB Delivers shielding from noise and vibration from motors, internal antennas, speakers and microphones Used as an interconnect for placing components between primary and secondary PCBs Available in a large range of effective heights to ensure efficient contact and EMI protection Normally take minimal space on a PCB Allows for normal soldering and pick-and-place installation with typical machines and tools Spring Contacts should be designed to work with PCBs as grounding or shielding contacts in addition to general electrical connection between secondary PCBs or other electrical components. When designed properly, spring contacts provide sound connection and electrical conductivity as well as EMI protection for sensitive components and are often used as an RFI shielding connection for metal boxes or other cabinet enclosures. The spring contact design ensures positive connection between mating surfaces, and works in conjunction with both wiping and sliding action. Many general designs are available including simple C-shaped and Box-shaped connectors, to Low profile connectors to address tight fit applications. Pre-loaded spring contacts provide consistent force applied over the working range of the spring contact with minimal deflection. Spring Contacts are generally used in the design of motion control units, mobile power units, environmental monitoring equipment, broadcast & communications equipment, and industrial process control equipment.

Share your thoughts with other customers for Faspro Technologies, Inc

Add Review