Welcome to Fastbolt

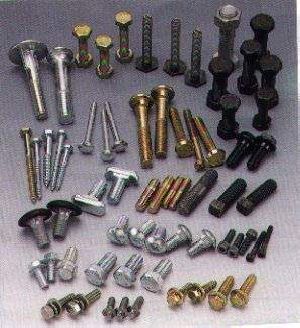

Manufacturer / Exporter / Supplier Of Threaded Fasteners, RIVETS-BLIND RIVETING SYSTEMS, WASHERS PINS, Wire Management, WASHERS RINGS

-

Year of Establishment

1974

-

Primary Business

Supplier

-

Number of Employees

50-99

Welcome to Fastbolt

Manufacturer / Exporter / Supplier Of Threaded Fasteners, RIVETS-BLIND RIVETING SYSTEMS, WASHERS PINS, Wire Management, WASHERS RINGS

Year of Establishment

1974

Primary Business

Supplier

Number of Employees

50-99

We provide a comprehensive selection of cable tie styles, sizes, and materials to satisfy a broad range of applications and environments. Ties that are adjustable, releasable, and reusable to improve productivity. Tools to provide faster, safer, and consistent installations. For use in a variety of applications and environments for long-term reliability. A range of easy, economical solutions to insulate, protect, bundle and color code cable and components. A comprehensive variety of styles and configurations to address applications and environments appropriately. There are hundreds of types of electrical connectors. Electrical connectors are characterized by their pinout and physical construction, size, contact resistance, insulation between pins, ruggedness and resistance to vibration, resistance to entry of water or other contaminants, resistance to pressure, reliability, and ease of connecting and disconnecting. We provide a comprehensive selection of cable tie styles, sizes, and materials to address these issues and environments.

Rivets are used in a numerous applications to secure two or more components together. Typically used in sheet type products, the rivet is easily installed with access only required from one side of the assembly. The standard blind rivet consists of two components, a rivet body and mandrel. The rivet is first placed into an installation tool and is then inserted into the application. Activating the tool pulls the rivet's mandrel, drawing the mandrel head into the blind-end of the rivet body. This action forms a head on the rivet body and secures the application materials together. Finally, the mandrel reaches its predetermined break-load, with the used portion of the mandrel breaking away and being removed from the set rivet. Blind rivets offer speed, consistent performance and excellent appearance.

There are many different types of washers including flat, lock, split, star, Belleville, and wave. Different types of washers have different uses. They can be made of aluminum, Brass, Stainless, Nylon, Bronze, Alloy, and Steel The key is the application it is being used for. Retaining Rings There are three main types of retaining rings available, each of which may then be broken down into sub-types depending on the application needs:

Internal threads refer to those on nuts and tapped holes, while external threads are those on bolts, studs, or screws. Threads can be produced by either cutting or rolling. Cut threading is a process by which steel is cut away from a round bar of steel to form the threads. Advantages of Cut Threading: Few limitations with regard to diameter and thread length. All specifications can be manufactured with cut threads. Disadvantages: Longer labor times. The weakest area of any mechanical fastener is the minor diameter of the threads. Since the thread dimensions of a cut thread and rolled thread fastener are identical, there is absolutely no difference in strength. However, cut threading interrupts the natural grain structure of the round bar whereas roll threading reforms it.

There are many different types of washers including flat, lock, split, star, Belleville, and wave. Different types of washers have different uses. They can be made of aluminum, Brass, Stainless, Nylon, Bronze, Alloy, and Steel The key is the application it is being used for. Retaining Rings There are three main types of retaining rings available, each of which may then be broken down into sub-types depending on the application needs:

Share your thoughts with other customers for Fastbolt

Add Review