Welcome to Gage-Line Technology, Inc.

Manufacturer / Exporter / Supplier Of Chart-Gages, Comparator Chart Engineering

-

Year of Establishment

1972

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to Gage-Line Technology, Inc.

Manufacturer / Exporter / Supplier Of Chart-Gages, Comparator Chart Engineering

Year of Establishment

1972

Primary Business

Supplier

Number of Employees

10-49

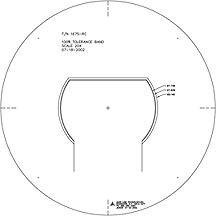

The chart-gage is a gage and it must be treated as such. The following considerations are important: • It should be made of a dimensionally stable material. Rigid material is preferred. • The humidity and temperature coefficients must be considered. • The lines on the chart-gage must be uniform in width with sharp edges. • The lines must withstand normal usage and cleaning. • They should be stored flat (never rolled) in a normal gage room environment. • They should be calibrated at intervals determined by the usage. • The Chart-Gage Master image should be produced with a precision plotter to .001” or better accuracy. • The final chart-gage should be accurate to ±.002 or 10% of the part tolerance times the magnification used, which ever is greater. • Calibration fiduciary marks should be included for dimensional control. Custom Optical & Digital Chart-Gages: We have over 60 years of experience in chart-gage and we will put this experience to work for you. A CAD file or a marked-up print along with the chart size and magnification is all that is usually required for us to price your custom Chart-Gage.

After Pearl Harbor, the USA had to rev-up quickly to fight in World War II. Optical gaging was instrumental in helping the war effort by permitting the manufacturing of parts in record time. It offered a way to guarantee interchangeable in manufacturing. This was a major problem at the time. By using optical gaging, it could be guaranteed that a screw manufactured on the west coast would fit a tapped hole manufactured on the east coast. It could also be guaranteed that vendors in various parts of the USA would produce parts within tolerance. This was accomplished by the customer sending duplicate chart-gages to his vendors. The chart-gages contained lines, which represented the tolerance limits of the parts. The Chart-Gages were used on optical comparators. The shadow of the part had to be within the tolerance zones on the Chart-Gage to be acceptable. It would be allowed to leave a vendor’s plant only if it met this criterion. Today, there are many ways to guarantee interchangeable and uniformity. However, optical gaging is often overlooked. If the engineer or manufacturer does not consider optical gaging in the control quality, he or she can be missing an opportunity to accomplish an inspection quickly, economically, and accurately, using lower labor grade employees. The part form can be seen at magnification and examined. Tangent points can be studied. Very small radii and other features can be easily checked when enlarged on the screen. These are a few reasons for considering optical gaging. Once a person becomes familiar with optical gaging he or she will use it more often. Quick measurements can be made using standard or custom Chart-Gages. Using a custom gage guarantees that each operator will accept parts to the same standard each time. Whether checking one or a thousand part, today or a year from now, the results will be the same.

Share your thoughts with other customers for Gage-Line Technology, Inc.

Add Review