Welcome to JENTEK Sensors, Inc.

Manufacturer / Exporter / Supplier Of the JENTEK Eddy Current Array Tester, JENTEK Core Competencies, Nondestructive Testing, Eddy Current Testing

Welcome to JENTEK Sensors, Inc.

Manufacturer / Exporter / Supplier Of the JENTEK Eddy Current Array Tester, JENTEK Core Competencies, Nondestructive Testing, Eddy Current Testing

• Engine Component Inspection • Blades, disks, IBRs, holes, etc. • NDT of Complex Structures (per ASTM E2884-13 Standard Guide for Eddy Current Testing of Electrically Conducting Materials Using Conformable Sensor Arrays, ASTM International, Book of Standards, Vol. 03.03.) • Surface breaking and subsurface cracks • Hidden corrosion • Coating Characterization without need of expensive custom calibration standards (per ASTM E2338-11 Standard Practice for Characterization of Coatings Using Conformable Eddy-Current Sensors without Coating Reference Standards, ASTM International, Book of Standards, Vol. 03.03.) • Complex Shaped Surfaces • Firtree slots in engine disks, fillets in aircraft structures, etc. • MaterialsProcess Quality Characterization

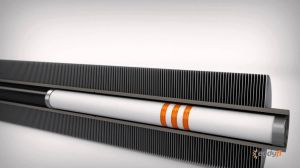

Nondestructive Testing for SCC Crack Mapping and Depth SizingMWM-Array Scanners for SCC Detection through Coatings Wide-area scanning arrays for preliminary screening of SCC through coatings (coal tar wrap, epoxy, etc.) Scan rates over 20 sq. ft.min (1.86 m2 ) using JENTEK’s GridStation 8200 instrumentation MWM-Array Scanners for High-Resolution SCC Crack Mapping & Sizing High-throughput C-Scan imaging of discrete cracks andor SCC colonies Conformable MWM-Array eddy current sensors configurable for wide range of pipe diameters Minimal surface preparation requirements (not affected by coatings, moisture and dirt) Crack Depth Software Module – JENTEK GridStation Software Rapid conversion of MWM-Array response into depth measurements Automatic crack interaction capability Electronic storage and retrieval of measurement data (as potential MPI replacement) Microsoft Windows™ environment with GridStation software for quick and easy report generation

JENTEK Founded in 1992 • JENTEK Core Competencies Model-Based Inverse Methods, Electronics Design, NDTNDENDI, SHM • JENTEK focus is improving safety and quality while delivering high ROI • MWM-Array • Winner FAAATA “Better Way” Award • National Tibbets Award • ASNT Best Paper Award • U.S. Navy Phase III Commercialization Award • FAA approved for some engine inspections • U.S. Navy Standard practice for engine inspection • Implemented on Space Shuttle Leading Edge at NASA KSC • Proven to provide improved inspection performance using model based multivariate inverse methods (MIMs) • GridStation Software and HyperLattice based MIMs • Intuitive operator interfaces • Inherent self-diagnostics • C-Scan imaging of multiple properties simultaneously (e.g. first and second layer corrosion, or coating conductivity and thickness) • Convenient procedure and data management

Share your thoughts with other customers for JENTEK Sensors, Inc.

Add Review