Welcome to MinVasive Components

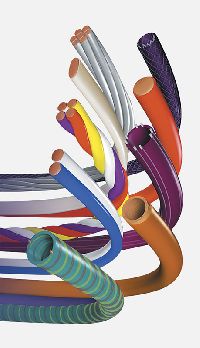

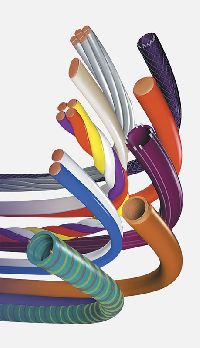

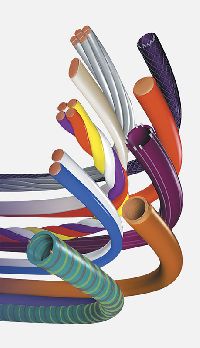

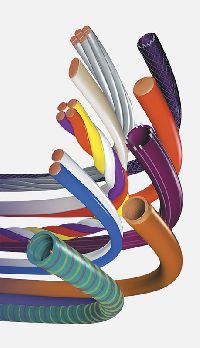

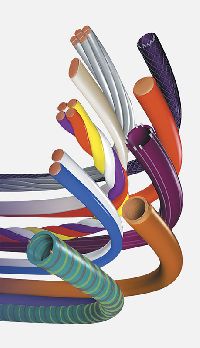

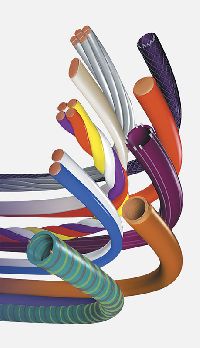

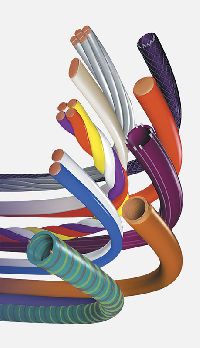

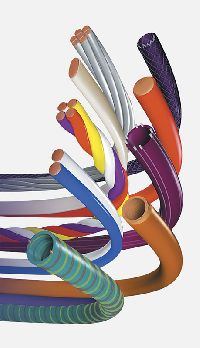

Manufacturer / Exporter / Supplier Of Polyimide Tubing, Twist Wire, Single End Wire, Polymer Tubes, Conductor Embedded Tubing, Lubricious Tubing, Thermoplastic Tubing, Hybrid Tubing, Reinforced Tubing, Twisted Wire

Welcome to MinVasive Components

Manufacturer / Exporter / Supplier Of Polyimide Tubing, Twist Wire, Single End Wire, Polymer Tubes, Conductor Embedded Tubing, Lubricious Tubing, Thermoplastic Tubing, Hybrid Tubing, Reinforced Tubing, Twisted Wire

HPC Medical Products uses a unique combination of ductility, strength, and stiffness to provide greater toughness and durability than competing polyimide-tubing designs. This becomes apparent during cyclical stress applications. In addition, repeated changes in bending, pressure, and tension do not compromise the structural integrity of our polyimide tubing.

We offer innovative micro-tubing products, including: braid, coil, and longitudinally reinforced tubes in both straight Polyimide and hybrid constructions.

Hybrid tubing typically consists of a polyimide base layer with a thermoplastic outer layer, is constructed from both thermoset polyimide and a thermoplastic polymer including: Our hybrid tubing is perfect for applications that require diameters of .0080 to .065 inches (.2032 to 1.651 mm) combined with the strength of polyimide as well as the added benefit of flexibility and thermal bonding.

Our proprietary coating process utilizes liquefied medical grade thermoplastics to create unique state-of-the-art polymer tubing and insulated wire products. The most popular resins are Pebax®, Nylon 11 and Nylon 12 (Vestamid®).

HPC Medical Products PTFE and low friction PD-Slick™ (a blend of PTFE and polyimide) are specially designed as medical tubing liner or as a wire coating. PD-Slick™ Features: Gamma radiation resistant USP Class VI biocompatibility Utilized used to coat the inside or outside diameter of a tubing product Lower friction with the material properties of polyimide

HPC medical Products offers Individually insulated and electrically isolated wires embedded in the tubing wall which can be spiral wrapped around the tube with up to 16 conductors.

Our pure polymer hybrid tubing can be cut to precise lengths as short as .05 inches, with a length tolerance of plus or minus .005 inches. We have the capability of cutting tubing with OD’s of .011 inches to .091 inches, for thermocouple caps, electrical insulating sleeves, as well as bundling collars for groups of wires or fibers.

HPC Medical Products provides single end wire with thin film insulation of cross-linked polymer insulation without sacrificing dielectric strength.

Our single-thermocouple (twisted) wires are joined by twisting them together down the length to form most types of thermocouples including Type T, J, and K. Any two conductors can be joined in this fashion. The twisted design is especially good for applications where the TC wires are being repeatedly flexed.

HPC Medical Products offers multiple ends of individual wires that have been insulated and then twisted or cabled into one continuous construction. Product Features This type of construction can make most Type T, J and K thermocouples. A single end wire is used to form a multi-end twisted construction.

Share your thoughts with other customers for MinVasive Components

Add Review