Welcome to National Bearings Co.

Manufacturer / Exporter / Supplier Of Thrust Bearings, Thrust Retainers, Thrust Washers, Thrust Discs, Cup Retainers, Radial Bearings, Cone Retainers

Welcome to National Bearings Co.

Manufacturer / Exporter / Supplier Of Thrust Bearings, Thrust Retainers, Thrust Washers, Thrust Discs, Cup Retainers, Radial Bearings, Cone Retainers

Thrust bearings are designed to support loads parallel to the axis of rotation. Single direction thrust bearings are composed of 2 races and a complement of balls. There are two common thrust bearings. Retainer-based thrust bearings – the retainer separates the balls reducing the load capacity but allowing for higher speeds. Full-complement thrust bearings – which contain a full complement of balls inside the bearings that touch one another. This design is intended for maximum load capacity and limited speed. National Bearings specializes in retainer-based custom thrust bearings because they offer tremendous flexibility in design, can withstand high speeds, and provide for greater customization to meet the needs of an application. Bearing DesignBy working with National Bearings, you can be assured our design team will create custom thrust bearings that precisely fit your need. We will individually address space, load, speed and environmental issues to create bearings that will match the lifecycle of your application without wasting resources on "one size fits all" thrust bearings.

Cup and Cone Retainers are engineered for use in angular contact bearing applications. The strength of the retainer, plus its ability to hold and separate balls, is obtained by National's unique method of manufacture and assembly of the ball in the retainer. In this method, the metal is "wrapped around" the ball to provide maximum ball retention with minimum friction between ball and cage. Custom Cup and Cone RetainerFor years, the cup and cone retainer has been thought of as a "bicycle ball bearing, " but realizing its possibilities, engineers have developed a host of new applications for it. For instance, opposing cup and cone retainers provide an economical combination radial and thrust bearing. The one-piece assembly permits automated assembly with machined, stamped, or plastic molded parts.

Thrust retainers hold and separate balls or needles in a thrust bearing to meet both the load and speed requirement of an application. Retainers can be used alone in an application or as part of a complete thrust bearing. National Bearings manufactures custom thrust retainers and has a large inventory of tooling to produce: Plastic Ball Retainer Stamped Thrust Retainers Plastic Ball Retainers Plastic Needle Retainers

Thrust Washers Thrust washers differ from standard washers or spacers because they must carry a bearing load and not wear out over time. To perform, thrust washers must be heat treated and then polished to achieve a hardness and surface finish that is equal to the bearing that is being supported. National Bearings maintains an extensive tooling inventory to produce hundreds of sizes and shapes including flat thrust washers, keyed thrust washers and tabbed thrust washers. If the exact size you need is not available, National can develop a custom thrust washer to meet your requirements.

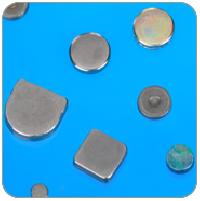

Thrust discs from National Bearings come in a variety of shapes and sizes. Thrust discs are also hardened and polished to support bearing loads. Sometimes called thrust slugs, thrust discs can be D-shaped, square, round or a custom shape to fit your application. They are often made in varying thicknesses to take up different tolerances in the same application. The parts can be color coded or marked for easy identification. Similar to thrust washers, custom sizes are available with quick turn-around, inexpensive tooling.

radial bearings from National offer the design engineer flexibility to create the ideal bearing. Rather than compromising the design to accommodate a standard bearing, a custom radial bearing can be tailored to meet the space, load, life cycle and performance criteria required. A properly designed bearing solution can reduce energy consumption, reduce wear, decrease deterioration, and simplify product assembly

Cup and Cone Retainers are engineered for use in angular contact bearing applications. The strength of the retainer, plus its ability to hold and separate balls, is obtained by National's unique method of manufacture and assembly of the ball in the retainer. In this method, the metal is "wrapped around" the ball to provide maximum ball retention with minimum friction between ball and cage. Custom Cup and Cone RetainerFor years, the cup and cone retainer has been thought of as a "bicycle ball bearing, " but realizing its possibilities, engineers have developed a host of new applications for it. For instance, opposing cup and cone retainers provide an economical combination radial and thrust bearing. The one-piece assembly permits automated assembly with machined, stamped, or plastic molded parts.

Share your thoughts with other customers for National Bearings Co.

Add Review