Welcome to PlastiFabLeed Plastics

Manufacturer / Exporter / Supplier Of Dipole Using Ultem, Insulator Cover, Housing Unit, Custom Block, Switch Board

-

Year of Establishment

1977

-

Primary Business

Supplier

-

Number of Employees

10-49

Welcome to PlastiFabLeed Plastics

Manufacturer / Exporter / Supplier Of Dipole Using Ultem, Insulator Cover, Housing Unit, Custom Block, Switch Board

Year of Establishment

1977

Primary Business

Supplier

Number of Employees

10-49

This part was fabricated in conjunction with a Non-Disclosed Defense Agency with classified use. Using customer supplied material, the material sheet was CNC Saw cut to workable size. Blanks were then milled on specialized table & spot checked continuously throughout run to ensure + .002 tolerance requirements. Parts were shipped to customer for assembly then sent back for final trims & finishes of assembled part allowing a zero margin for error to customer requirement.

This part was fabricated in conjunction with a Non-Disclosed Defense Agency with classified use. Using customer supplied material, the material sheet was CNC Saw cut to workable size. Blanks were then milled on specialized table & spot checked continuously throughout run to ensure + .002 tolerance requirements. Parts were shipped to customer for assembly then sent back for final trims & finishes of assembled part allowing a zero margin for error to customer requirement.

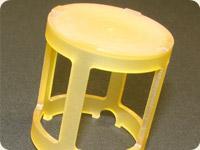

This part was fabricated in conjunction with a Non-Disclosed Space Agency with classified use. Using customer required material, the material sheet was CNC Saw cut to workable size. Blanks were then milled on specialized table & spot checked continuously throughout run to ensure + .005 tolerance requirements for multiple cylindrical cavities & holes. Special attention was needed in regard to shrinkage & load relief of part resulting in specialized placement of part while machining.

Share your thoughts with other customers for PlastiFab/Leed Plastics

Add Review