Welcome to Saint-Gobain Ceramic Materials, Boron Nitride Products

Manufacturer / Exporter / Supplier Of Thermal Fillers, Industrial Powders, Lubricant Additives, Cosmetic Powders, Machinable Ceramics, Planar Diffusion Sources

Welcome to Saint-Gobain Ceramic Materials, Boron Nitride Products

Manufacturer / Exporter / Supplier Of Thermal Fillers, Industrial Powders, Lubricant Additives, Cosmetic Powders, Machinable Ceramics, Planar Diffusion Sources

Thermal Fillers CarboTherm Boron Nitride Thermal Fillers | Saint-Gobain CarboTherm™ BN Thermal Fillers The best choice for today's electronic cooling and plastic applications CarboTherm™ Boron Nitride powders offer the unique combination of high thermal conductivity and dielectric strength in one material. Today's smaller, hotter, and faster electronic assemblies require greater heat dissipation than ever before. Polymers filled with CarboTherm powders solve these problems in a wide variety of applications. When used as a cooling filler in a variety of resin systems, CarboTherm powder is unmatched where application requires good heat dissipation, low dielectric loss, and low thermal expansion. Thermal conductivity of single crystal CarboTherm is >300 WmK. Thermal conductivity of about 95% dense polycrystalline granules is >125 WmK. Overall thermal conductivity of a CarboTherm filled resin matrix in a given application and processing parameters will depend on the inherent thermal conductivity of the resin, filler packing density, particle-to-particle interfacial contact, as well as material composition. CarboTherm™ Boron Nitride powders are inert, white ceramic materials featuring a platey, hexagonal crystal structure that offers certain benefits: High thermal conductivity for efficient heat dissipation from component assemblies Low density, light weight properties for higher filling and lower total cost of fillers Low dielectric constant for guaranteed performance of electronic devices High lubricity reduces wear and tear of processing equipment Non-abrading properties enable gentle handling of critical electronic components

Industrial Powders Combat Boron Nitride Industrial Powders | Saint-Gobain Combat® BN Industrial Powders The cornerstone of Saint-Gobain Advanced Ceramics Combat® Industrial Boron Nitride powders are pure, white, ceramic materials with a hexagonal crystal structure similar to graphite. Commonly known as "white graphite, " hexagonal BN (hBN) is a synthetic ceramic produced by reacting Boron source and a Nitrogen source at temperatures above 1600°C. The resulting product is a lubricious white powder that has excellent high temperature stability (oxidation resistant up to 900°C) and lubricating properties. A non-toxic white (clean appearance), and a non-conductor of electricity, boron Nitride offers an excellent substitute for other commonly used powder lubricants in a variety of industrial applications such as graphite, molybdenum disulfide, and organic waxes and oils. In most cases, boron nitride substantially improves the efficiency of these applications. Non-wet by molten metals Chemically inert and corrosion resistant Lubricious at temperatures up to 1800°C in inert atmospheres Excellent high temperature stability and oxidation resistant in air up to 900ºC High thermal conductivity for efficient heat dissipation from components Non-toxic, safe for human contact and the environment White, clean appearance Improved alternative to solid lubricants such as graphite and molybdenum disulphide

Combat® Boron Nitride -- machinable ceramics solve problems that could not possibly be tackled with other ceramics Boron Nitride machinable ceramic is made by hot pressing Boron Nitride powders at high temperature and pressure. Combat Boron Nitride can easily be machined into rods, bars, plates and even intricate custom shapes. The unique combination of highly exceptional thermal, physical and chemical characteristics of Combat Boron Nitride ceramic makes it ideal for solving tough challenges in a wide range of industrial applications. Excellent thermal shock resistance High electrical resistivity High thermal conductivity Good chemical inertness High temperature material Excellent lubricating properties -- low coefficient of friction Non-wetting (without oxidation) High dielectric breakdown strength Excellent machinability A Note on Combat® Boron Nitride Ceramic Properties by Orientation Hot pressed boron nitride, sometimes referred to as "white graphite" has a platey, hexagonal structure. Atoms in the basal or platelet plane are held together by strongly directed covalent bonds in a hexagonal array. This type of bond, similar to that found in diamonds, yields excellent physical, thermal and electrical performance under a wide range of uses. In contrast, the bonds between platelet layers are weak Van der Waals forces, resulting in highly directional or anisotrophic properties. Although these weak bonds can reduce the physical strength of the overall material, they impart many unique electrical and mechanical properties, most notably, its lubricious nature. Hexagonal Boron Nitride can be easily machined into complex shapes using conventional high speed cutting tools.

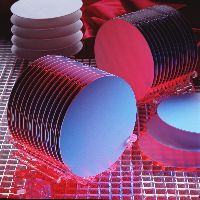

Planar Diffusion Sources Saint-Gobain's Boron Nitride group is the leading supplier of solid planar diffusion sources (PDS) to the semiconductor industry, used for doping silicon wafers. In fact, PDS® Products are used by more than 150 semiconductor device manufacturers in 17 countries. PDS® Products are preferred for use in applications requiring a high concentration of dopant, to dope large diameter silicon, particularly 150mm diameter, and in high volume production. PDS Products allow semiconductor fabricators to replace hazardous chemical dopants such as boron trichloride, boron tribromide, diborane, phosphorus oxychloride, and phosphine.

Lubricant Additives Idealube® BN Lubricant Additives | Saint-Gobain Idealube® Boron Nitride Lubricant Additives High-temperature industrial lubrication solutions from Saint-Gobain Idealube® Boron Nitride Lubricant Additives are hexagonal boron nitride powders (BN) with lamellar structures similar to graphite. In addition, Idealube BN lubricant additives are electrically insulating, are unmatched in thermal conductivity, have low coefficients of friction and oxidation resistance at high temperatures (up to 900°C), and are naturally white. Compared to other solid lubricants, only Idealube has this unique combination of properties, making them the perfect solution for the most challenging applications. In applications involving moving parts, heat dissipation and wear resistance can mean success or failure of a design. Idealube® BN lubricant additives offer the solutions in most extreme operating conditions other solid lubricants such as graphite, MoS2 or PTFE fail. With the growing demand for lubricants with improved heat dissipation, better wear rates and oxidation resistance, Idealube Boron Nitride is the solution that leads to less frequency of lubrication, lower lubricant usage and less downtime. Idealube® additives are used in a wide range of applications such as food processing equipment, high-temperature greases and oils, anti-seize compounds, dielectric greases, release agent for gaskets and seals and many more. Excellent high temperature stability and oxidation resistant in air up to 900ºC Low coefficient of friction, lubricious at temperatures up to 1800ºC (inert atmospheres) High thermal conductivity for efficient heat dissipation from moving parts Chemically inert and corrosion resistant Non-toxic , safe for human contact and the environment White, clean appearance

Share your thoughts with other customers for Saint-Gobain Ceramic Materials, Boron Nitride Products

Add Review