Listing ID #1915123

Company Information

Ask for more detail from the seller

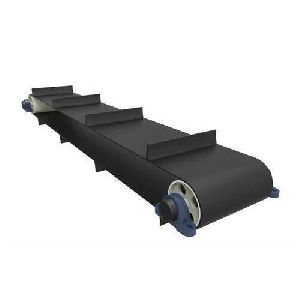

Contact SupplierWith our know-how and latest equipment in the industry, we are engaged in offering the best range of Conveyor Belts. Being an admirable Manufacturer and Supplier, we try to live up to our reputation. Different types of conveyor belts are available for conveying different material like PVC and rubber. Their excellence is tallied to the quality as required by industrial standards. Get in touch to avail them at pocket friendly price.

More About Conveyor Belts

Speed

Troughing Angle

Drive

Idlers

Belting

| Material | Max. Slope |

|---|---|

| Crushed Limestone | 15o |

| Iron Ore | 15o |

| Coal | 15o |

| Lignite | 15o |

| Cement Bags | 0o |

| Other | 15o |