Welcome to Woomin Technology Co., Ltd.

Manufacturer / Exporter / Supplier Of Mud Treatment System, Shale Shaker, Mud Cleaner, Desander, Desilter, Mud Gas Separator, Decanter Centrifuges, Vacuum Degasser, Air Pressure Pneumatic System

Welcome to Woomin Technology Co., Ltd.

Manufacturer / Exporter / Supplier Of Mud Treatment System, Shale Shaker, Mud Cleaner, Desander, Desilter, Mud Gas Separator, Decanter Centrifuges, Vacuum Degasser, Air Pressure Pneumatic System

We are offering desilter a hydrocyclone much like a desander except that its design incorporates a greater number of smaller cones. As with the desander, its purpose is to remove unwanted solids from the mud system. The smaller cones allow the desilter to efficiently remove smaller diameter drill solids than a desander does. For that reason, the desilter is located downstream from the desander in the surface mud system.

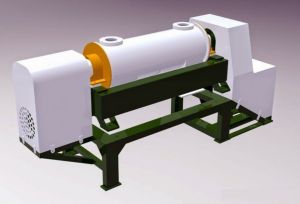

We are offering pneumatic system compressor air receiver tank air generated in the compressed air stored in a storage installed in the lower booster air nozzle and the compressed air is injected in the liquid raw material is transported to the air devices. The facility is usually a source of air using a compressed gas feeding device, the feed pipe, the intermediate gas separating device and the transfer to the powder, etc. Is required. Device placement is proper selection of the powder to be able to be transported over several hundred meters. Features several common supply pipe in one single supply unit can supply several collecting tank can be discharged as the arrangement and operation of both the plant and has flexibility. Flow rate can be easily controlled continuously monitors the input and output can be checked. This machine is a full automatic operation is possible. Can handle the pneumatic system and the different types of powders, chemical, pharmaceutical, paint, mining, smelting and metal used.

We are offering decanter centrifuge decanter centrifuge separate the suspending fluids using the principle of centrifugal action, the suspending fluids is pushed into the rotor drum through the inlet pipe and the fluid hole of the spiral feeder. Under the influence of centrifugal force, solid phase particles are pushed to the internal wall of the drum, then to the nud export of the small end of the drum and excreted. But the fluids is excreted from the overflow hole of the large end. Such cycle is in order to achieve the purpose of continuous separation.high speed decanting centrifuge are effective for separation.

We offer Shale Shaker. 1. Shale Shaker Shale shakers are components of drilling equipment used in many industries, such as coal cleaning, mining, oil and gas drilling. They are considered to be the first phase of a solids control system on a drilling rig, they are used to remove large solids also called cuttings from the drilling fluid, more commonly called “Mud” due to its similar appearance. Drilling fluids are integral to the drilling process and, among other functions, serve to lubricate and cool the drill bit as well as convey the drilled cuttings away from the bore hole. These fluids are a mixture of various chemicals in a water or oil based solution and can be very expensive to make. For both environmental reasons and to reduce the cost of drilling operations, drilling fluid losses are minimized by stripping them away from the drilled cuttings before the cuttings are disposed of. This is done using a multitude of specialized machines and tanks. Shale shakers are the primary solids separation tool on a rig. After returning to the surface of the well the used drilling fluid flows directly to the shale shakers where it begins to be processed. Once processed by the shale shakers the drilling fluid is deposited into the mud tanks where other solid control equipment begin to remove the finer solids from it. The solids removed by the shale shaker are discharged out of the discharge port into a separate holding tank where they await further treatment or disposal. Shale shakers are considered by most of the drilling industry to be the most important device in the solid control system as the performance of the successive equipment directly relates to the cleanliness of the treated drilling fluid.

We offer Mud Treatment System. Drilling Mud System Application Field Drilling Mud Cleaning Systems are widely used for Oil Gas drilling mud circulation, Horizontal directional drilling mud recycling, geothermaldrilling, mining, coal exploration drilling, water well drilling etc.WOOMIN have experience for drilling mud cleaning solutions in all kinds of drilling. WOOMIN drilling fluid system is turnkey solution with first time commissioning service, training up of users engineer for operating the mud system. WOOMIN Equipment for drilling mud systems Shale Shaker, MudCleaner , Desander , Desilter, Centrifuge, Degassers, Agitator, Mixing Hoppers, Flare Igniter, Various Tanks, Pumps etc All phased of drilling mud cleaning equipment to clean your drilling mud for different types of drilling .

We are offering mud gas separator mud gas separator is commonly called a gas-buster or poor boy degasser. It captures and separates large volume of free gas within the drilling fluid. If there is a “kick” situation, this vessel separates the mud and the gas by allowing it to flow over baffle plates. The gas then is forced to flow through a line and vent it to a flare. A “kick” situation happens when the annular hydrostatic pressure in a drilling well temporarily (and usually relatively suddenly) falls below that of the formation, or pore, pressure in a permeable section downhole, and before control of the situation is lost.

We are offering mud cleaner. Degasser is a device used in drilling to remove gasses from drilling fluid which could otherwise form bubbles. For small amount of entrained gas in a drilling fluid, the degasser can play a major role of removing small bubbles that a liquid film has enveloped and entrapped. In order for it to be released and break out the air and gas such as methane, h2s and co2 from the mud to the surface, the drilling fluid must pass degassing technique and it can be accomplished by the equipment called degasser which is also a major part of a mud systems. Vacuum type is the most common form of degasser. It can be horizontal, vertical or round vessel. A vacuum action is created to pull in the gas cut mud. When the liquid enters the tank it will flow and be distributed to a layer of internal baffle plates designed for the mud to flow in thin laminar film and is exposed to a vacuum that forces the gas to escape and break out of the mud.the vacuum pump moves the escaping gas from the vessel discharging it to the rig’s flare or environmental control system.

We are offering vacuum degasser. Vacuum type degasser degasser is a device used in drilling to remove gasses from drilling fluid which could otherwise form bubbles. For small amount of entrained gas in a drilling fluid, the degasser can play a major role of removing small bubbles that a liquid film has enveloped and entrapped. In order for it to be released and break out the air and gas such as methane, h2s and co2 from the mud to the surface, the drilling fluid must pass degassing technique and it can be accomplished by the equipment called degasser which is also a major part of a mud systems. Vacuum type is the most common form of degasser. It can be horizontal, vertical or round vessel. A vacuum action is created to pull in the gas cut mud. When the liquid enters the tank it will flow and be distributed to a layer of internal baffle plates designed for the mud to flow in thin laminar film and is exposed to a vacuum that forces the gas to escape and break out of the mud.the vacuum pump moves the escaping gas from the vessel discharging it to the rig’s flare or environmental control system.

We are offering desander. Desander and desilter are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. Desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers. Normally the solids diameter for desander to be separated would be 45~74μm, and 15~44μm for desilter.

Share your thoughts with other customers for Woomin Technology Co., Ltd.

Add Review