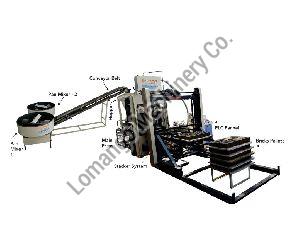

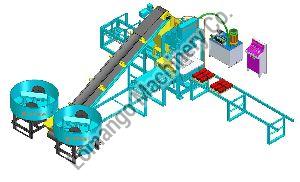

Lomango Machinery Co. is known as top Manufacturer, Exporter, Supplier, Retailer, Service Provider and Trader of best Industrial Molds, Paver Block, Paver Moulds, Block Making Machines and Cement and Concrete.

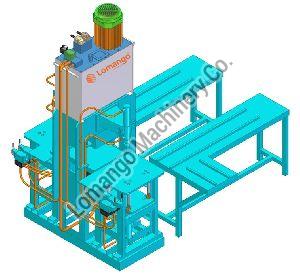

Certainly, here's a description of the automatic fly ash brick making machine manufactured by Lomango Machinery: --- **Introducing the Lomango Machinery Automatic Fly Ash Brick Making Machine** At Lomango Machinery, we take immense pride in presenting our state-of-the-art Automatic Fly Ash Brick Making Machine, a cutting-edge solution designed to revolutionize the brick manufacturing industry. With a strong commitment to quality, efficiency, and sustainability, our machine is engineered to meet and exceed the diverse needs of the construction sector. **Key Features:** 1. **Eco-Friendly:** Our machine makes efficient use of fly ash, a byproduct of thermal power plants, significantly reducing waste and contributing to a greener environment. 2. **High Productivity:** The Lomango Machinery Automatic Fly Ash Brick Making Machine boasts an impressive production capacity, ensuring you meet your project requirements with ease. 3. **Precision and Consistency:** Equipped with advanced hydraulic systems, our machine molds bricks with unparalleled precision, resulting in consistent quality and strength. 4. **User-Friendly Interface:** With an intuitive control panel, operators can easily monitor and adjust production parameters, ensuring a seamless manufacturing process. 5. **Customization:** We understand that every project is unique, which is why our machine can be adjusted to produce bricks of various sizes and designs. 6. **Energy Efficiency:** Our machine is designed with energy-saving features to reduce operational costs while upholding environmental responsibility. **Production Process:** 1. **Raw Material Mixing and Feeding:** The machine starts by mixing fly ash, cement, sand, and water in precise proportions, ensuring a homogeneous mixture. 2. **Automatic Brick Molding:** The mixed material is fed into the molding chamber, where it is compressed using hydraulic technology, resulting in perfectly shaped bricks. 3. **Brick Ejection:** Once molded, the bricks are automatically ejected onto a conveyor belt or pallet, minimizing manual handling. 4. **Curing and Drying:** The bricks are moved to a curing area where they are cured with steam or water to enhance their strength and durability. 5. **Stacking and Palletizing:** In the final stage, the bricks are stacked and palletized for easy transportation or storage. **Why Choose Lomango Machinery:** - With our commitment to quality and innovation, we provide reliable and durable machines that stan