Welcome to Mechcon Industrial Solutions Pvt.Ltd.

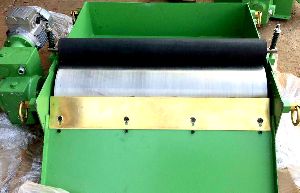

Established in the year 2012 at Pune, (Maharashtra, India), as“ Mechcon Industrial Solutions Private Limited ” that is engaged in Design, Engineering, Manufacturing and exporting of a wide range of Turnkey Projects in Bulk Material Heandling.. Read More