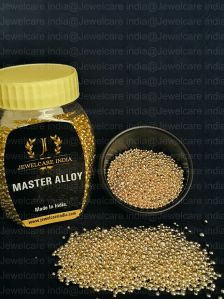

- MOQ 2 Kilogram

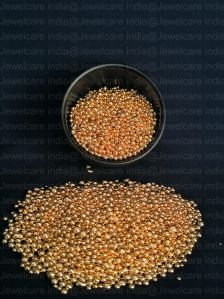

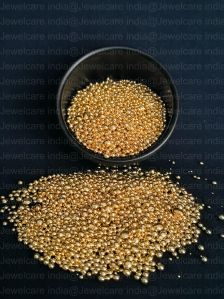

- FormGrains

We are offering master alloys for gold. master alloys for carat gold & silver jewellery ================================================== alloy code :- sp 141 composition (wt. %) : ag 23, cu 66, zn + deoxidizers bal. Carat : 10 - 14 color : american yellow melting temp of alloy : 890 c application: the alloy sp 141 is the most widely used alloy for diamond set jewelry. It imparts yellow color that is very popular in export market. It is usable from 10 to 14 carat investment cast jewelry. It ensures smooth surface finish and porosity-free finished products. Reusability of the castings is also very satisfactory. Recommended practice: 10k 14k application : casting casting h-made alloying temp. : 1010c - 1020c 1030c - 1040c casting temp. : 980c - 1000c 1010c - 1030c flask temp. [normal cast] : 620c - 640c 620c - 640c flask temp. [stone cast] : 580c - 620c 580c - 620c quenching time : 15 - 20 minutes. 15 - 20 minutes notes: â�¢ the actual casting temperatures and flask temperatures shall be decided by the parameters like the section thickness of the items (thick, medium or thin), the overall sizebulk of the cast tree, the design intricacies etc. Â�¢ as a thumb rule, for thinner sections higher temperatures are selected and for thicker sections lower temperatures are preferred. At the same time, designs demanding higher form filling capabilities, higher than normal temperatures are an obvious choice. Â�¢ cast tree cleaning & drying procedure: after primary removal of the investment during quenching, submerge tree in a hot (80-100oc) 50% phosphoric acid solution for 15-20 minutes. Rinse well with cool water to remove remaining