Company Information

Ask for more detail from the seller

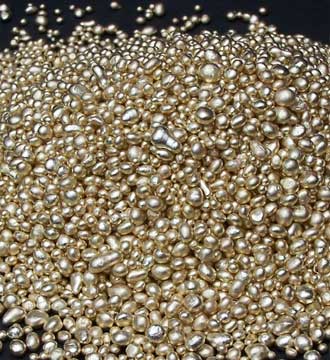

Contact SupplierComposition (Wt. %) : Ag 23, Cu 65, Zn + Deoxidizers- BAL.

Carat : 18 - 22

Colour : Indian Yellow

Melting Temp of Alloy : 890 Ce.

Application: The alloy SP 181 is the most widely used alloy for diamond jewelry. It imparts

right set of properties which helps artisans to achieve firm diamond setting. It also gives a

color which is popular for 18 carat diamond studded Indian jewelry.

Recommended Practice:

18K 22K

Application : Casting H-made Casting H-made

Alloying Temp. : 1040C - 1060C 1060C - 1080C

Casting Temp. : 1020C - 1050C 1050C - 1070C

Flask Temp. [Normal Cast] : 630C - 650C 640C - 660C

Flask Temp. [Stone Cast] : 610C - 630C 620C - 640C

Quenching Time : 10 - 15 minutes. 15 - 25 minutes

Notes:

1) The 18 carat casings have a tendency to get hardened and subsequently give

problems of cracking especially when flasks are cooled very slowly. For this reason,

it is recommended that the flasks are cooled as fast as permitted by the quality of

diamonds and also by the design parameters.

2) Pre-Alloying is strongly recommended simply to ensure better homogeneity in

castings as well as in hand made products. Also, for still better results, pre-alloying

in an inert atmosphere is always preferred.

4) Cast Tree Cleaning & Drying procedure: After primary removal of the investment

during quenching, submerge tree in a hot (80-100oC) 50% phosphoric acid

solution for 15-20 minutes. Rinse well with cool water to remove remaining

investment powder and base metal oxides. Dry with compressed air.