Our Products

Industrial Machinery

1 Products availablePrinting Machines

1 Products availablePaper Work & Making Machinery

1 Products availablePaper Cutting Machine

1 Products availableSheet Metal & Turned Components

1 Products availableTextile Machinery

1 Products availableLamination, Wrapping & Banding Machines

1 Products availableOur Complete range of products are Paper Handkerchief Machine, Labor Protection Gloves Dipping Machines, Latex Toy Balloon Production Line, Multifunctional Small Latex Products Dipping Machine and Multifunctional Small Special Shapes Latex Products Dipping Machine.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

the jumbo roll paper cutting machine refers to cutting the big bobbin rewinding into a small paper, used for tissue paper machine and toilet paper machine

main features:

1. Gassing axis used to make paper tube is accurate, simple

2. Embossing system: using steel to steel blank holder, independent gas steel adjustment, convenient adjustment, each layer of paper stratification;

3. Horizontal type unwinder, paper is pneumatically loaded on machine, save manual handling.

4.paper is pneumatically loaded on machine by wide leather, each roll of jumbo paper are independent tension adjusting device.

5. Adopts inching switch before and after drawing the jumbo roll paper, simple and safe operation.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

feature and functionrn1.put a roll in the form of flat belt push, equipped with stepless speed regulating device, rolling tension can be adjusted.2.embossed steel roller on wool roller (according to customer requirements using other material embossing roll).3.folding adopt vacuum adsorption form.4.each part adopt synchronous belt.5. Can produce different specifications of the models according to the requirement, can increase 1-4 color flexo printing device.technical parameters

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package

Delivery Time : 60 days after payment.

tf-dz glove dotting machinernuse: get in on the gloves surface with a layer of pvc particles. To enhance gloves anti-skid and durabilityrncharacteristic:

1, characteristics:the machine is controlled by computer, combined mechanical and electrical

2, using photoelectric sensor, accurate control points of the machine automatically, driving action.

3, using a special quartz infrared heating tube, plastification heating on pvc particles.to improve the adhesion of pvc.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

Semiautomatictoiletpapermachinesfeatureandfunction

1.Pneumatictensionroll, adapttothehighlowgradepaperproduction

2.Cuttingbylargeround-knife, theknifebodystrongrigidity, lightrunning, nonoise, novibration

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

Feature and functionrn1.Using PLC programmable control systemrn2, The man-machine dialoge control, display the production parametrs on screem rn3.Jumbo roll paper is pneumatically loaded on machine, unwinding roll tensioncontrol device.4.The rewinding process of the product is tight first and loose afterward, with itstension adjustable.5.Punch length is adjustable.6.Paper core replacement, glue spraying and paper cutting undergo automaticallyaccording to given sequence.7.Embossing pattern is to be selected by clients.8.The bearings, , electrical components and synchronous belts are using famous brandrn9.According to the requirements of customers can do double embossing roll, and can assorted with rubber composite device to product the kitchen paper as also 1-3color printing equipment.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

Technical parametersrn1.Power source: 220V 50HZrn2.Total power: 2.3KWrn3.Output: 30 bales/minrn4.Rejection rate: Less than 5%rn5.Packing size: (100-290)*(70-150)*(25-120)MMrn6.Machine size: 1000*850*1350MMrn7.Weight: 150KG

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

introduction

automatic two sides glove dotting machine

use: get in on the gloves surface with a layer of pvc particles. To enhance gloves anti-skid and durability

characteristic:

1, characteristics:the machine is controlled by computer, combined mechanical and electrical

2, using photoelectric sensor, accurate control points of the machine automatically, driving action.

3, using a special quartz infrared heating tube, plastification heating on pvc particles.to improve the adhesion of pvc.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

introduction

tf-bjx labor protection gloves dipping machines 1, machine according to various materials (natural rubber, butyronitrile, pvc) pu curing process of humanized design, reasonable process, automatic balance fill glue system, make products to be stable, uniform coating thickness, length, no hanging point, temperature uniformity, high output, easy to demould, etc.

2, oven using hot air circulation principle, the internal temperature of the oven, with high performance of insulation materials, ensure the temperature loss effectively, thus improve the thermal efficiency of the machine, the machine automatic temperature control system is adopted for the heating system, with high performance control switch, improve the accuracy of temperature control, so as to improve the product percent of pass.

3, special design of the elasticity of the piston mold connection device, mould replacement is simple, no off mold phenomenon.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

introduction

tf-ysx latex gloves production line technical characteristics

1, adopt the most advanced gloves production technology and production process layout, product qualification rate is more than 98%, protein content is lower than 120 micrograms per gram;

2, tpu coating technology

3, imported surfactant solidifier, finished membrane is uniform, no powder mold release

4, the introduction of foreign advanced transmission main chain structure, chain little resistance during operation, production of high speed, stable operation

5, a main motor drag, solve the drag, difficult to synchronize, fault point, difficult maintenance, and other issues

6, adopt vertical hot air circulation drying oven, compared with other forms of hot air circulation, save energy consumption by almost 20%

7, used for cleaning mold splitter six roller long hair scrub mould technology;

8, mold directional, machine printing technology;

9, a variety of specifications of production, on the same edge automatic adjustment, the pu edge roller, long service life;rn10, can design according to the needs of customers of different length, height, cost models;

.Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

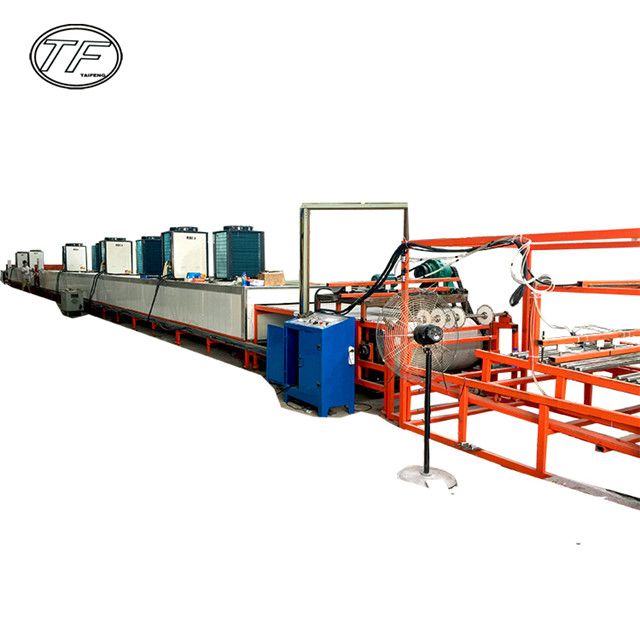

automatic soft ceramic tiles production line

1) brief description:

this set of equipment is suitable for producing all kinds of different soft ceramic tiles, what's more, the biggest different point from traditional production process is that it has already achieved to continuously produce, and the production efficiency has got more innovational rising by contrast with previous traditional production process. In addition, production line can be custom made as per buyers' requirements, for instance, splitting and rewinding can be finished on the progress of running, and it can be cut in all kinds of different specifications and shapes, and then automatic being packaged at the same time. It is ideal option for mass production.

item name: soft brick building material production facility/softy ceramic tile manufacturing line

technological process : natural color sand is its key material, equipped with high-molecular polymer, fiber resistance and advanced composite material, it will be finished in auto production line and after through press coating, dehydration, finished, cutting etc.

facility flow process (length: 47-70-80m)stir system- stone-like coating/multi-color paint coating equipment-three-dimensional drying system-rewinding system- cutting dedicated devicern

production power: 150kw.production capacity: 2200m2/24hoursrnworker: 6-8 people/shift

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

introduction

1.natural latex toy balloon production line adopts continuous production method and direct leaching method, uniform film-forming, beautiful in color, a variety of specifications and different ball can be producted at the same time, also can produce a variety of specifications color balloon; production line length have 35 meters, 60 meters, 80 meters and so on a variety of specifications, can automatic demoulding, high output, the product without the hanging point.

2.the machine is designed with more humanity according to natural latex curing forming process. It has reasonable process, latex self-balancing system, so that the quality of the gloves can be stable, the thickness and the length of the balloons can be uniform, no hanging points, heated evenly, high output, stripping balloons easy and simple.

3.the oven adopts the hot air circulation principle so that the internal temperature of the oven is even, uses fiber asbestos insulation materials to ensure the temperature does not drain, thereby improving the use of the thermal efficiency of the machine. The heating system of the machine uses pid temperature intelligent instrumentation, with high-performance control switch, improves the accuracy of temperature control, thereby enhancing the pass rate of the balloons.

4.specially designed mold with flexible piston connecting device, make the mold replacement is simple to operate, no balloons drop off happens.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

small paper rewinding machinernintroduction small paper rewinder refers to cut the jumbo roll paper cutting into large rolls of toilet paper, mainly used for hotels, airports and other large public toilets.

main features:

1. Gassing axis used to make paper tube is accurate, simplern

2. Embossing system: using steel to steel blank holder, independent gas steel adjustment, convenient adjustment, each layer of paper stratification;

3. Horizontal type unwinder, paper is pneumatically loaded on machine, save manualhandlingrn

4. Paper is pneumatically loaded on machine by wide leather. Each roll of jumbo paper are independent tension adjusting devicern

5. Adopts inching switch before and after drawing the jumbo roll paper, simple and safeoperation.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

Brief introduction of production line:

1.The natural latex product line adopts the plate type direct immersion way, the film formation is uniform, the color is bright, the production line length is 25 meters, may produce the balloon, the finger cover, the air bag, the condom and many kinds of unusual latex products and so on.

2.The machine carries on the humanized design according to the natural latex solidification molding craft, has the flow reasonable, the automatic balance restores the glue system, causes the product to be stable, the coating thickness and thin length is uniform, has no droop point, the temperature is uniform, Production output can be customized according to customer requirements, easy and simple demoulding and other characteristics.

3.The oven adopts the principle of hot air circulation, which makes the oven temperature even and chemical fiber asbestos insulation material, which effectively ensures that the temperature will not be lost, thus improving the use of the heat efficiency of the machine. The machine heating system adopts PID temperature intelligent instrument. With high-performance control switch, improve the accuracy of temperature control, thereby improving the product's qualified rate.

4, specially designed elastic piston type die connection device, the replacement die operation is simple, no drop die phenomenon appears;

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

1.The natural latex product line adopts the plate type direct immersion way, the film formation is uniform, the color is bright, the production line length is 25 meters, may produce the balloon, the finger cover, the air bag, the condom and many kinds of unusual latex products and so on.

2.The machine carries on the humanized design according to the natural latex solidification molding craft, has the flow reasonable, the automatic balance restores the glue system, causes the product to be stable, the coating thickness and thin length is uniform, has no droop point, the temperature is uniform, Production output can be customized according to customer requirements, easy and simple demoulding and other characteristics.

3.The oven adopts the principle of hot air circulation, which makes the oven temperature even and chemical fiber asbestos insulation material, which effectively ensures that the temperature will not be lost, thus improving the use of the heat efficiency of the machine. The machine heating system adopts PID temperature intelligent instrument. With high-performance control switch, improve the accuracy of temperature control, thereby improving the product's qualified rate.

4, specially designed elastic piston type die connection device, the replacement die operation is simple, no drop die phenomenon appears;

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.