Welcome to Heavypressmachines Corporation

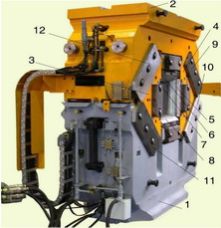

We are a well-known Russian Heavypressmachines corporation , which one has been founded in 1955 as a factory for manufacturing the Heavy-Duty Forging and Press Equipment . We are manufacture: FOUR DIE FORGING HAMMER Has no analogues in the world! DEVICE can be installed on your hydraulic functioning press appropriate capacity! Designed for four-side radial forging performed by hydraulic forging presses up to 120 MN. Devices are mounted on hydraulic forging press as conventional forging dies. These four die forging devices are used for forging of ingots and blanks from all ductile steel grades, alloys and non-ferrous metals. The device is designed for simultaneously four-side radial forging of ingots and billets in wide range of grades and shapes in hydraulic open-die forging press. Models KB800 KB1250 KB2000 KB3150 KB6300 BENEFITS: The use of this device results in : -1.5-2.5 times increased efficiency of the forging process. -7-13% increased good metal yield due to reduction of surface defects and the number of blank heating times. -1.7-2.0 times decreased allowances thus allowing to save from 30 up to 70 kg of metal per 1 t of forged parts. Min. 1.5 times reduced power consumption per 1 t of forged parts -increase in metal recovery by 15-50 % via decreasing tolerances -energy savings by 2-4 times -improved structural isotropy of metal and its physical-chemical properties -wide range of steel grades and sectional shapes forgeable. Additional info to our --------- OURS AUTOMATIC FORGING SYSTEMS AND PRODUCTION LINES: 1.1 Automatic System for hot forming of M20-M36 nuts, bearing races, sleeves and gears Model AKA-O334.31, rated force of 2.5 MN 1.2 Automatic Production Lines for hot forming of semi-finished bearing races, gears, sleeves, nuts and crosses 1.3 Automatic Production Line for bore-hole sucker rods forming 1.4 Automatic Production Line for railway clamps forming Type APC-4 1.5 Automatic Production Line for manufacturing of T-head and binder bolts for railways fastening 1.6 Automatic Production Line for manufacturing of railway fastening spikes 1.7 Cold Former designed for production of M20-M24 bolts, ball pins etc. 1.8. 6-station Cold Former designed for production of piston pins, plug housings and other parts of the same type 1.9 5-station Cold Formers designed for production of semi-finished nuts, bushes, rollers, etc. 1.10 Automatic System for forming of stepped roll-type parts, shafts and bushes 1.11 Automatic Thread Rolling Machines 1.12 Automatic Line for production of hexagon nuts 1.13 Automatic machinery System for production of bimetal band blanked parts 1.14 Special Automatic Machine for blanking parts from band material in rolls 1.15 8-station Automatic Sheet- Presswork Machines 1.16 Automatic Sheet- Presswork machines with bottom drive 1.17 Special Automatic Nail Making Machine 5.1 Multipurpose Horizontal Forging Machines with vertically split dies for hot die forming of rod stock 5.1 Multipurpose Horizontal Forging Machines with vertically split dies for hot die forming of rod stock 5.2 Automatic Horizontal Forging Machines with vertically split dies 5.3 Automatic Horizontal Forging Machine with horizontally split dies 2.1 Hydraulic Presses for Hot or Cold Sheet Presswork Double-action presses with hydraulic cushion upto 25.0/16.0 MN Single-Action Presses upto 50.0 MN 2.2 Hydraulic Presses for Hot Die Forming upto 50.0 MN 2.3 Hydraulic Presses for Large-sized Electrodes and Blocks Production Hydraulic Presses for Manufacturing of Pipe Elbow Bends Special-Purpose Hydraulic Presses For welding electrodes production For refractories production For Superhard Materials Synthesis For hot forming of friction products For Hot Forming of intricate-shaped parts made of steel, titanium and non-ferrous metal PLATE-BENDING MACHINES -Plate bending machines with mechanical drive. -Three-rols plate bending machines -Four -rolls plate bending machines -Hydraulic Four -rolls plate bending machines Four -rolls plate bending machines for shells bending from corrugated plate metal. 4.1 3-Roll Plate-bending Machine 4.2 4-Roll Plate-bending Machines for bending of cylindrical and taper parts in hot and cold state RADIAL SWAGING MACHINES 6.1 Machinery System based on Radial Swaging (Forging) Machine with two manipulators for production of parts from cut-to-length rod- and pipe stock by means of hot and cold forming technique 6.2 Radial Swaging (Forging) Machine for hot forging of stepped shafts and pipes 6.3 Radial Swaging Machine for on-mandrel cold forging of products with shaped or plain hole ON-RAIL FORGING MANIPULATORS from 12.5KN upto 300 KN BRIQUETTING PRESSES

-

Manager Foreign trade centre Heavypress

Schein

-

Year of Establishment

1955

-

Primary Business

Manufacturer

-

Number of Employees

1001 - 5000

-

Annual Turnover

USD 100 to 1 Billion Approx.