Company Information

Ask for more detail from the seller

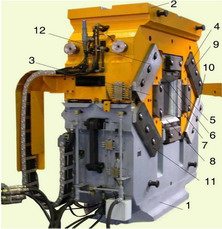

Contact SupplierWe are offering Four Die Forging Hammer

has No Analogues in the World!

device Can Be Installed On Your Hydraulic Functioning Press Appropriate Capacity!

Designed for Four-side Radial Forging Performed By Hydraulic Forging Presses Up to 120 Mn.

devices are Mounted On Hydraulic Forging Press as Conventional Forging Dies.

these Four Die Forging Devices are Used for Forging of Ingots and Blanks from all Ductile Steel Grades, Alloys and Non-ferrous Metals.

the Device is Designed for Simultaneously Four-side Radial Forging of Ingots and Billets in Wide Range of Grades and Shapes in Hydraulic Open-die Forging Press.

models Kb800 Kb1250 Kb2000 Kb3150 Kb6300

benefits:

the Use of this Device Results in :

-1.5-2.5 Times Increased Efficiency of the Forging Process.

-7-13% Increased Good Metal Yield Due to Reduction of Surface Defects and the Number of Blank Heating Times.

-1.7-2.0 Times Decreased Allowances Thus Allowing to Save from 30 Up to 70 Kg of Metal per 1 T of Forged Parts. Min. 1.5 Times Reduced Power Consumption per 1 T of Forged Parts

-increase in Metal Recovery By 15-50 % Via Decreasing Tolerances

-energy Savings By 2-4 Times

-improved Structural Isotropy of Metal and Its Physical-chemical Properties

-wide Range of Steel Grades and Sectional Shapes Forgeable.