Welcome to ThermoDynamix Engineering

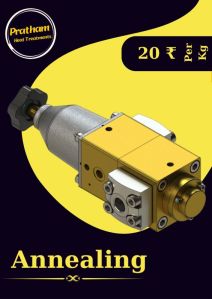

Thermodynamix engineering cnc turning heat treatment shot blasting ms, ss fabrication heavy machining (vtl) job work company unit I - a2/8a, baramati co-operative industrial estate, bhigwan road, baramati, dist – pune, maharashtra- 413102 unit ii -33a, b u bhandari industrial estate, sanaswadi, tal – shirur, dist – pune, maharashtra- 413102 direct no. +91-9325311389, +91-7350066993 email id- located at sanaswadi, pune nagar highway & chakan shikrapur highway, 33 kms from pune & 235 kms. From mumbai year of establishment – 2012 registration – ssi (msmed) registration no. – 270251201712 cst tin – 27240625757/ c w.e.f. 7-9-2007 mvat tin no. – 27240625757/ v w.e.f. 7-9-2007 service tax code – acqpn3281jsd0002 iec code – pan no – acqpn 3281 j range – baramati division – pune ix contact person – mr. Hemant n. Nimbalkar (+91-9325311389), nitin h. Nimbalkar (+91-7350066993) type of organization – proprietary concern, (pvt ltd. Reg. In process) nature of company – commercial heat treaters, cnc turning & machining for forging & foundries, fabrication of ms & ss tanks vessels for food industry, heavy machining with 20000 sq. Ft. & 70 hp power connection with 15 team members working in 3 shifts on reliever basis with 125 kva generator backup production process – hardening, tempering, stress relieving, annealing, normalizing, solution annealing, liquid nitriding* & isothermal annealing * (*under installation) certification – approved by ibr & in process of ts 16949 testing facility – hardness testing – in house by optical brinell hardness testing & rockwell hardness tester, metatech make microscope for microstructure testing of material connected supply – 60 hp existing (125 kva generator backup) as applied for ht line connection annual capacity – 6000 mt, 500 metric ton per month. Our valued customer 1. Devyani alloys pvt ltd 2. Ghatge patil industries ltd 3. Hitech boiler mfg co. 4. Piaggio vehicles pvt ltd. 5. Radheya machining ltd. 6. Pioneer engineering 7. Mahalaxmi seamless pvt. Ltd. 8. Maruti steel fab we introduce ourselves as commercial heat treaters, cnc machining and fabricators for heavy steel industries conveniently located in the industrial hub of baramati and sanaswadi, india pune. Catering to hardening, cnc machining needs and fabricating, constructing and design needs of auto ancillaries, general engineering industry, oil engine manufacturers and all types of foundries. We are equipped with state of art automatic plc controlled heat treatment furnaces, capable of hardening wide variety of components like liners, shafts, spindles, gear, engine valves, ball heads, lever etc. And all types of fabrication set up including electric hoist of 3 mt . We continuously strive to improve processes to aim at zero % rejection. Our team experience in heat treatment and cnc turning, machining, heavy fabrication in foundry, automobiles companies and auto ancillaries. We have been in the business for over 15 years and thankful to our clients for their support over the year. We are equipped metallurgical laboratory with all test equipments like optical brinell hardness tester, rockwell hardness tester, microscope with image analyses software, sample preparation machines. Presently we are follows the api (american petrochemical institutes) standards (appendix 6h 2009), and the astm standards for the material testing. We properly calibrated the furnaces quarterly and all other instruments of the testing. Manufacturing facility s. No. Furnace capacity process/installation 1 bogie type four burners plc controlled automatic, dual fired max. Temp 1140* 2.5mt hardning temparing/ iso thermal annealing 2. Vertical turrent lathe with digital dro -2 nos. Height-1mtr 150 swing vertical turning 3 shot blasting m/c automatic, hanger type, monorail type 1000kg/ batch shot blasting 4 water quenching tank & turbo high velocity agitator cooling tower. 9000 ltr. 3. Hp agitator quenching tank 5 cranes – 4 nos. 3 m.t. & 1 mt material handling equipment 6 welding transformers -4 nos tag, mig arc wel fabrication ms, ss parts facilities at sanaswadi, pune plant 1 bogie type four burners plc controlled automatic max. Temp 1250 c 2000kg annealing, hardening normalizing, stress releaving tempering 2 oil quenching tank with turbo agitator - high velocity and cooling tower. 8000 ltr quenching tank 3 cranes 3 mt-1 & 15mt-1 material handling equipment 4 liquid nitriding furnace nitriding furnace 5 continuous furnace hardning temparing 500 kg/hr hardning temparing insothermal 6 jyoti cnc dx 150 and dx 200 3a cnc turning machines 7 siden (russian) make vertical turrent lathe with digital dro height- 1.4 mtr. Swing- 2.5 mtr. Vertical turning 8 turning leths 2 for turning machining 9 welding transformers -4 nos tag, mig arc welding for fabrication of ms, ss components 10 sand blasting machines 2 surface cleaning.

-

Manager Procurement

Nitin

-

Year of Establishment

1991

-

Primary Business

Service Provider

-

Annual Turnover

Rs. 0.5 to 2.5 Crore Approx.