Listing ID #6806283

Company Information

Ask for more detail from the seller

Contact SupplierProcess Overview – Process of heating metal without letting it reach its molten state and then cooling it in a controlled manner to achieve desired mechanical properties. The Heat Treatment consists of : a) heating cycle in which the part is heated at a consistent rate till a certain temperature b) soaking cycle in which the part is held at a particular temperature c) cooling cycle in which the part is cooled using different cooling media to achieve the desired properties. The cooling cycle is the most crucial stage of HT cycle as it determines the final grain structure thereby influencing the mechanical properties of the metal. Heat Treatment is broadly classified as Bulk and Surface Heat Treatment.

Few common Bulk Heat Treatment process performed by us are :

Annealing and Normalizing – These processes are used to refine and homogenize the grain structure to remove residual stresses and improve machinability. The only difference between Annealing and Normalizing is the former is furnace cooled and the other is air cooled.

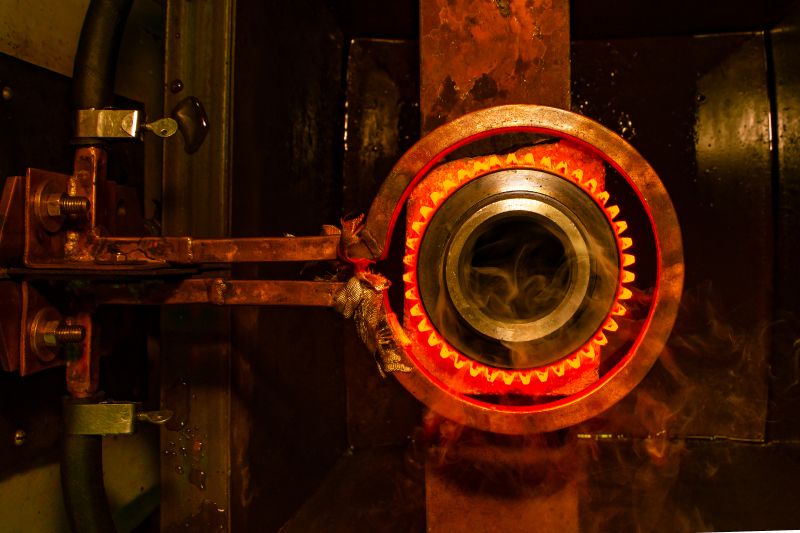

Hardening and Tempering – The purpose of hardening is to increase the hardness of steel by producing a fully martensitic structure through controlled cooling rate whereas tempering is to relieve the residual stresses induced during hardening and improve toughness and ductility of steel. Hardening is mainly characterized by composition of alloy, type of quenching medium and size and shape of part.

Few common Surface Heat Treatment process performed by us are :

Carburizing - It is a thermochemical process in which carbon is diffused into the surface of low carbon steels to increase the carbon content to sufficient levels so that the surface will respond to heat treatment and produce a hard, wear-resistant layer.

Nitriding – It is a thermochemical process in which nitrogen is diffused in alloy steel to form a hard surface. It is further classified as Gas, Liquid and Plasma nitriding based on the media being used.

Carbonitriding – It involves diffusion of both carbon and nitrogen into the surface of steel substrate.

Capabilities

All heat treatment processes under one roof

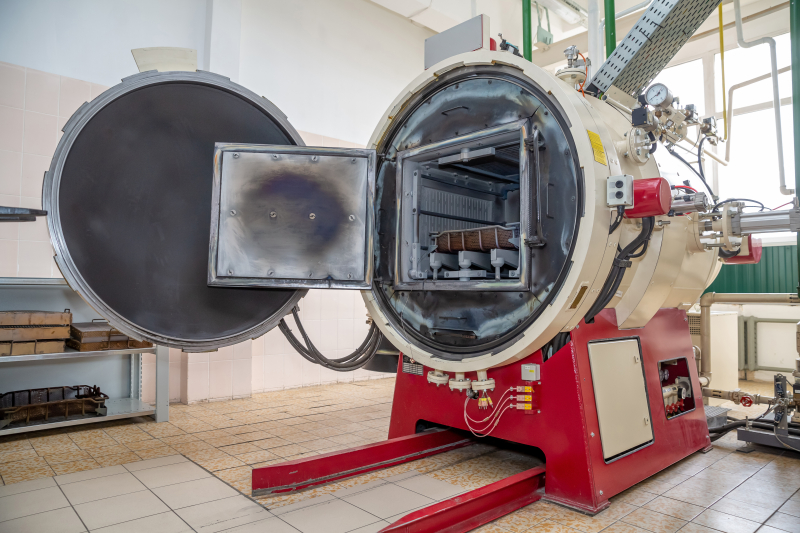

Completely automated and PID controlled heat treatment furnaces

Paperless recording of heat treatment cycle with complete traceability

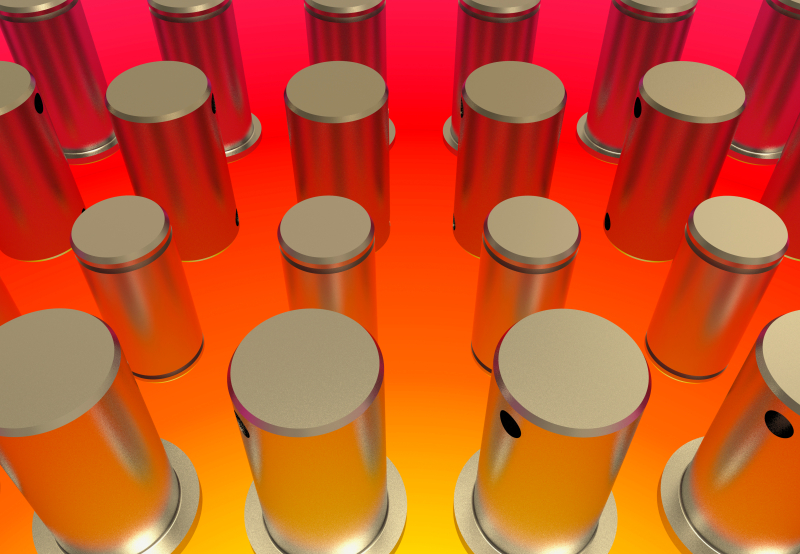

Multiple furnaces to cater mass production

Flexibility to load batch and production parts

Vertical furnace up to 2 meter Dia and 8 meter height for loading of long shafts and rollers

Heat treatment of raw as well as machined parts

In-house and third-party testing of heat-treated material for verification of required mechanical properties

Heat Treatment facility certified to ISO 9001 and IATF 16949 Quality Management System

Periodic calibration, maintenance, leak testing and temperature uniformity survey to ensure process reliability and consistency

Application and Benefits

Heat Treated steels are used in almost every industry sector such as Aerospace, Automotive, Oil & Gas, Power Generation, Steel, Pumps and Valves, Hydraulic, Air and Gas Compressor, Construction etc.

Heat Treatment is the most effective and efficient method of achieving the desired mechanical properties by altering the grain structure of a conventional steel. Few advantages of Heat Treatment are as follows :

Improving wear and corrosion resistance

Improve fatigue strength

Improve toughness

Increase machinability by improving malleability and ductility

Improve cold press property

Improve other properties such as magnetic, thermal, and electrical properties

Established in the year 2021 with an aim to provide end to end manufacturing assistance to Technology and Engineering companies located overseas for their product development cycle. The Company has a manufacturing setup in the prime location of Navi Mumbai giving it a strategic access to an extensive supplier network catering across industry sectors such as Aerospace, Automobile, Steel, Energy, Plastic etc. and correspondingly providing an excellent connectivity to our overseas customer through Air and Sea.

We are committed to provide the finest of manufacturing experiences with minimal intricacies and management troubles. We work with you to co-create innovative and futuristic products while ensuring 100% delivery of its value & service. We have established a global ecosystem comprising of : critical part suppliers, outsourcing vendors, business partners, industry experts and consultants having expertise across wide range of industry domains such as castings, forgings, additive manufacturing, machining, welding, heat treatment, surface engineering, sheet metal, tool and die making, plastics and polymer, electronics and automation etc.

Our Vision

Establishes an ecosystem for holistic development of innovative, breakthrough and futuristic products.

Our Mission

Provide World Class Manufacturing services to at least 100 customers by the year 2025

Quality Assurance

At Innowerx, Quality consciousness is at the heart of each business activity. We have a structured and well-defined Quality Management System in accordance with ISO 9001:2015 and AS 9100 Rev.D standards. Customer requirements are thoroughly reviewed, clearly documented, and effectively communicated down the supply chain to ensure 100% compliance at the end of project/product life cycle. The quality tools implemented by us to ensure zero defects and zero customer complaints.

Our Leadership

A true visionary entrepreneur with great leadership qualities and the zest to focus on perfection, excellence, and smart work. His goal is to create a legacy and have the ability to contribute to the society through his vigor and work. Having had a total work-ex of 8 years, Mr. Kudva started his professional journey as a Production Engineer to get deep insights on the manufacturing challenges that are faced by the industry. Slowly developing a passion for problem solving and business management he took on to the leadership role in our sister concern Associated Plasmatron Private Limited as the Administrative Director in just a span of 5 years. While acting in this role he has been able to formulate business targets, restructured the Quality Management System and got the Company certified for AS 9100; correspondingly having faced the AS 9100 audits for 4 consecutive years and has aced well at every juncture.

He has been able to redefine the business process flow and automated it through a customized online ERP system; won several accolades for the Company, organized by Clients and Industry Associations such as the Most Sustainable Partner Award and SME National Productivity Championship. A Mechanical Engineer passed out from Mumbai University, he continued to develop his industrial skill set through various certification courses. Alongside, he holds a postgraduate qualification in MBA and is an alumnus at the S.P. Jain Institute of Management, Mumbai which has given him major backing and knowledge about the business world.