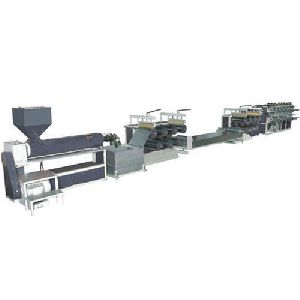

- Part LengthTurning - Up to 8 in. Milling - Up to 20 in.

- Machinery Axis3 4

- Equipment CapabilitiesCNC Control Capabilities Manual Control Capabilities

- EfficiencySix Sigma Practices Lean Manufacturing Principles

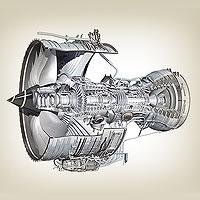

- Machining ProcessesMilling Drilling Boring Turning Threading External Internal Broaching Counterboring

At Plastic Products, Inc., we provide precision metal machining services for a wide range of industries and applications. Through our 20, 000 sq. ft. facility we are able to machine complex designs with short lead times – generally 20 to 40 days. We deliver world class quality and precision in any part or component we manufacture. We offer an expanded selection of conventional and specialty machining processes, including but not limited to milling, drilling, turning, threading, tapping, counterboring and countersinking, reaming, and broaching. Our machining capabilities can achieve tolerances as close as ±0.0005" on both CNC and manually controlled machines. This service is geared towards the machining of stainless steel, aluminum, as well as exotic materials such as brass, cobalt, nickel, and Inconel. As an established quality manufacturer, we are based on a culture of quality. The use of Six Sigma and Lean methodologies are SOPs, and our facility is ISO 9001:2008 certified with an AS9100C certified quality system. In addition to machining we can also provide parts design consultation, short run production and cell site manufacturing. The following processes are available through our approved vendor list such as passivation, grinding, material selection, and heat treating. Our facility can accommodate smallsingle to medium volume orders on lead times of four to six weeks, or shorter intervals for rushexpedited circumstances.