Welcome to Varahi Engineers & Fabricators

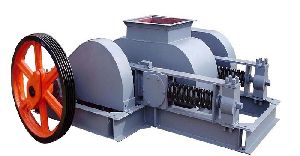

Manufacturer / Exporter / Supplier / Retailer Of Air Lock Valve, Lumps Breaker Machine, Roller Crusher, Rotary Air Lock, Lump Crusher, Jet Mills, Gyro Screen, Laboratory Jaw Crusher, Industrial Ice Crusher Machine, Single Toggle Jaw Crusher, Lump Breaker, Micro Pulverizer, Heavy Duty Jet Mills, Air... Read More