Listing ID #56378

Company Information

Ask for more detail from the seller

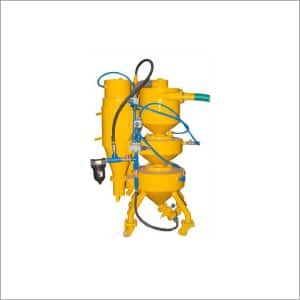

Contact SupplierWe offer Vacuum Blaster p-15r is a high performance blast machine for quick removal of mill scale, rust, weld slag, old paint etc. It has it's own integral system of instant recovery of abrasive, dust and debris. No flying dust and abrasive to contaminate surrounding.

portable:

mounted on 4-wheels. It can be wheeled to job site. Needs only one man to operate.

blasting at high speed & high velocity:

the abrasive is pressure fed to blast gun, it is propelled at high force against work surface, thus increasing blasting output.

uniform cleaning & finishing:

abrasive is cleaned of dust and debris in reclaimer before being recharged from blast nozzle. This ensures uniform surface finishing all the time.

re-use of abrasive:

metallic abrasives like c.i. Grit and steel shots are used several times. Media recycling is automatic. Any type of abrasive except sand can be used depending upon surface to be cleaned and finish required.

easy control:

start/ stop control is located at blast gun for ease of operator.

safe operation:

operator need not wear air-fed helmet or to work inside the blast room. He is fully safe. He works in dust free conditions. Vacuum recovery is made possible either by pneumatic or by electric vacuum pump.

dust free operation:

dust, debris and used abrasive are recovered at the blast point. No flying of dust and abrasive into surrounding area. Work can go on uninterrupted e.g. Painting can be done along with blasting.

how it works:

the system of p-15r machine is shown here in diagrammatic cross-section; the arrows marked in green indicate abrasive flow from abrasive tank which is a pressure vessel, to blast gun and its return via vacuum hose to reclaimer. The arrows marked in red represent recovery of debris and dust from blast gun. Abrasive is pressure fed from abrasive tank :

to blast gun

blast gun remains in close touch with surface to be cleaned. After cleaning the surface, abrasive, debris and dust is vacuum conveyed to reclaimer.

where good reusable abrasive is air washed and sieved and then returned to abrasive tank (a) for reuse. Dust and debris is trapped by cyclone.

and dust collector

thus only clean air is discharged into the atmosphere. Reverse air flow (vacuum) is created by compressed air ejector or by vacuum pump.

blast gun pressurizes stream of abrasive at the work surface and automatically transfers all dust, debris and used abrasive to reclaimer via a vacuum hose. Four castor wheels facilitate movement along work surface. A nylon brush surrounds the gun body to prevent escape of abrasive and dust.