Listing ID #556119

Company Information

Ask for more detail from the seller

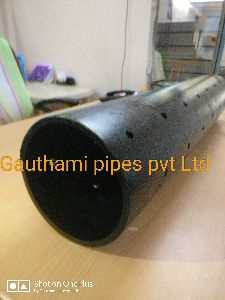

Contact SupplierWe are suppliers of wide range of HDPE Pipes. These PE Pipes are designed in conformation with international quality and strict adherence to varied standards such as IS: 4984, IS: 14333, IS: 14151, ISO: 4427, ASTM - D 2239, D 2447, D 3035, F 714, AS AE - 435, AS � 2698.1, BS � 6437, DIN-8074/5 design and testing code to match the quality of our products and services. Even in heavy-loaded areas, where only the strongest � Galvanized, Iron, Ductile iron, Cement Pipe survive, Plastic in the form of HDPE has scored beyond doubt as an ideal substitute. HDPE is today, the internationally preferred piping material across an unbelievable range of applications (where strength & long life are key requirements). HDPE is also capable of handling even semi-solid and gaseous effluents and displays unmatched resistance to corrosive chemicals. In other words where metal, cement and other forms of plastics fail to perform, HDPE pipes excel. Raw Material HDPE Pipes are manufactured from virgin raw material. The wide varieties of material such as PE-63, PE-80 and PE-100 have varied MRS (Minimum Required Strength) values. Both excellent weathering ability and resistance to UV light can be obtained by utilizing the correct material configuration available in the market. Applications HDPE Pipes can act as an ideal substitute for Galvanised iron, Cast iron and other material pipes � appropriate for varied applications such as Potable Water Services or Distribution lines, Sewerage & Drainage, Electrical Ducting, Natural Gas distribution, Irrigation, Waste Disposal, Industrial & Mining applications, Offshore pipeline installations under different climatic conditions as also or transportation of major aggressive chemicals. We can supply pipes ranging from 20 mm OD to 1400 mm OD of pressure range PN 2.5 to PN 16. Features & Benefits of HDPE Pipes