Listing ID #3864937

Company Information

Ask for more detail from the seller

Contact Supplier

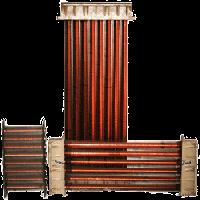

features of plate-fin heat exchanger

main features of plate-fin heat exchanger are as follows:

1. high heat transfer efficiency

the heat transfer efficiency is high is that the fin can cause the disturbance for the fluid to make the thermal boundary layer rupture and renew continuously. The heat transfer coefficient of forced convective gas is 35 to 350 w/ (m2·℃), the overall heat transfer coefficient of forced convective oil is 120 to 1740 w/ (m2·℃), while the overall heat transfer coefficient of gas-gas in the shell-and-tube heat exchanger is only 10 to 35 w/ (m2·℃).

2. compact structure and light weight

its heat transfer area per unit volume is generally 1500 to 2500 m2/m3, which is 8 to 20 times that of the shell-and-tube heat exchanger. The weight of aluminum plate-fin heat exchanger is one tenth that of the shell-and-tube heat exchanger with the same heat transfer area, but its metal consumption per unit heat transfer area can be dozens of times smaller than the shell-and-tube heat exchanger.

3. wide range of application

it can be applicable to the heat transfer of various different fluids such as gas to gas, gas to liquid and liquid to liquid. Depending on the arrangement and combination of various flow passages, the plate-fin heat exchanger can adapt to the heat transfer in different working conditions such as countercurrent, cross flow, multi-flow and multi-pass flow. The plate-fin heat exchanger can be shaped and produced in batch to meet different requirements, so the cost can be reduced and the interchangeability is enlarged.

4. the manufacturing process is complicated and the requirements for manufacture are strict.

5. it is easy to be blocked and the cleaning and maintenance are difficult. If the inner leakage occurs owing to the corrosion, it is hard to maintain the exchanger.

in the practical production, the plate-fin heat exchangers made of aluminum are used for air separation device, petrochemical device and mechanical power equipment, and their service ranges are as follows:

the design temperature is from -200 to 150℃, and the design pressure is from 0 to 0.6mpa.

|

TECHNICAL DATA |

||

|

MOC-CORE |

TYPES OF FINS |

FLOW TYPE |

|

Aluminium Alloy |

Plain Type Fin |

Cross Flow |