Listing ID #1574910

Company Information

Ask for more detail from the seller

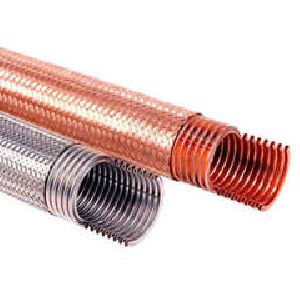

Contact Supplier1. CONSTRUCTION

AMBICAFLEX stainless steel corrugated hose construct from stainless steel strip that is rolled and the edges welded together to form a thin-walled, gas-tight tube. After the tube has been welded, corrugations are formed into the tube to make it flexible. Corrugations are formed into the tube either mechanically or hydraulically (Hydro forming).

2. CORRUGATION PROFILE

There are two corrugation profiles, annular and helical.

a. ANNULAR PROFILE

In the Annular Profile Independent corrugations, straight and parallel.

b. HELICAL PROFILE

In the Helical Profile One continuous corrugation that spirals around the hose

3. WIRE BRAIDING

To give corrugated hose the ability to withstand pressure, stainless steel wire is braided over the hose. Hoses may be single braided (one layer of braid) or double braided (two layers of braid) to achieve even greater working pressures. Braided braid is used on large-diameter hose. Designing the proper braid for each type of corrugated hose requires sophisticated engineering to maintain the proper balance between the braid strength and the hose’s flexibility.

4. CONSTRUCTION MATERIAL OF HOSE

5. CONSTRUCTION MATERIAL OF WIRE BRAIDING

6. APPLICATION

7. ANUULAR CORRUGATED HOSE SPECIFICATION

| Nominal Inside Diameter MM (Inch) | Minimum Bend Radius MM (Inch) | No. Of Braid | Maximum Working Pressure Kg/Cm² | ||||||

| 6 (¼") | 110 (4 ½") |

|

|

||||||

| 12 (½") | 135 (5 ½") |

|

|

||||||

| 19 (¾") | 200 (8") |

|

|

||||||

| 25 (1") | 225 (9") |

|

|

||||||

| 32 (1 ¼") | 250 (10") |

|

|

||||||

| 40 (1 ½") | 275 (11") |

|

|

||||||

| 50 (2") | 325 (13") |

|

|

||||||

| 63 (2 ½") | 400 (16") |

|

|

||||||

| 75 (3") | 450 (18") |

|

|

||||||

| 100 (4") | 550 (22") |

|

|

||||||

| 125 (5") | 700 (28") |

|

|

||||||

| 150 (6") | 800 (32") |

|

|

||||||

| 200 (8") | 725 (29") |

|

|

||||||

| 250 (10") | 850 (34") |

|

|

||||||

| 300 (12") | 1100 (44") |

|

|

8. HELICAL CORRUGATED HOSE SPECIFICATION

| Nominal Inside Diameter MM (Inch) | Minimum Bend Radius MM (Inch) | No. Of Braid | Maximum Working Pressure Kg/Cm² | ||||||

| 6 (¼") | 55 (2 ¼") |

|

|

||||||

| 12 (½") | 75 (3") |

|

|

||||||

| 19 (¾") | 125 (5") |

|

|

||||||

| 25 (1") | 225 (9") |

|

|

||||||

| 32 (1 ¼") | 155 (6 ¼") |

|

|

||||||

| 40 (1 ½") | 235 (9 ½") |

|

|

||||||

| 50 (2") | 275 (11") |

|

|