Listing ID #4333349

Company Information

Ask for more detail from the seller

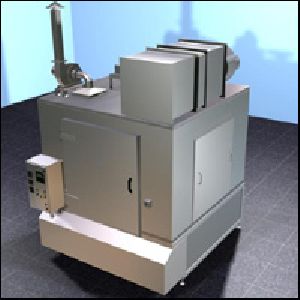

Contact SupplierA.M.P Rose chocolate moulding lines have been designed with the chocolate manufacturer in mind – high quality precision engineered assemblies have been developed through years of experience in the chocolate manufacturing industry.

With the focus on reliability, reduced maintenance, cleaning and downtime these lines ensure high efficiency rates even on 24/7 production.

The chocolate moulding line is constructed in modules, making the line extremely flexible and allowing for future expansion, or the addition of further modules such as nut or biscuit placing.

Synchronously matched Servo motors are used to drive the chains on a continuous basis, thereby ensuring smooth mould flow throughout the plant. Motor torque settings are monitored and if overloaded will stop the plant in the event of a problem. The moulds used have centre pin mounts on continuously moving chains, which ensures smooth mould transition throughout the plant and reduces breakages to a minimum. Mould presence and mould pin detection sensors are also provided.

A Servo motor moves the Depositor in a linear motion at exactly the same speed as the mould chains, which eliminates intermittent motions and allows for high speed depositing cycles on the chocolate moulding line.

The drives to the Right and Left side Depositor pistons are also via Servo motors, providing excellent control and flexibility. The Depositor can be set for spot or ribbon deposits, ensuring clean and accurate moulding , whilst maximising line speed and minimising moving parts.

‘One-shot’ products can be made on the depositor, typically at up to 60% filling rates. Centres such as caramel, praline, fondant, crème and jelly can all be used.

The Depositor has been designed for quick product change-overs. Most products can be changed through the HMI and with suitable nozzle plates. The HMI stores the pre-set recipes and they can be recalled at the touch of a button. Where change from one piston block to another is necessary, an optional ‘quick release’ block can be provided. The depositor is mounted at a height that is convenient for the operator to monitor all functions from ground level.

The 60mm thick insulated doors are clad in food-grade stainless steel are therefore hygienic and easy to clean and at the same time reducing plant noise to a minimum. These doors provide complete insulation, thereby ensuring that the correct cooling profile is maintained across the full length of the plant. The doors are hinged to allow access from both sides, and panels have windows and interior lighting where inspection is necessary.

All these special features combine to ensure that products made on A.M.P Rose moulding lines are of the best quality, with perfect shapes and with high gloss and smooth surface finishes.

Optional Modules Specifications & Capacities

The A.M.P Rose chocolate moulding line can be made to produce all kinds of chocolate slabs and articles, for example with fruit or nut inclusions, or with wafer or biscuit inside. Due to their modular design these lines can also be extended at a later date, either to increase capacity or to add specific modules. For whole or chopped nuts for example an additional nut/chocolate mixer could be added as a simple retro-fit.

Whole Nuts – A nut feeding system can be supplied to feed whole nuts into the mould cavities.

Inclusions – Chopped nuts, rice crisp pieces, raisins and other fruit pieces can be incorporated into the chocolate prior to depositing.

Chocolate with Biscuit – A biscuit placing system can provide a new product range.

Chocolate with wafer sticks – A cut and place module for wafer sticks/books can be incorporated into the moulding line.

Aerated Chocolate – Add texture whilst giving away less product with the addition of an aerated chocolate depositor.

OUTPUT

MOULD SIZE