Company Information

Ask for more detail from the seller

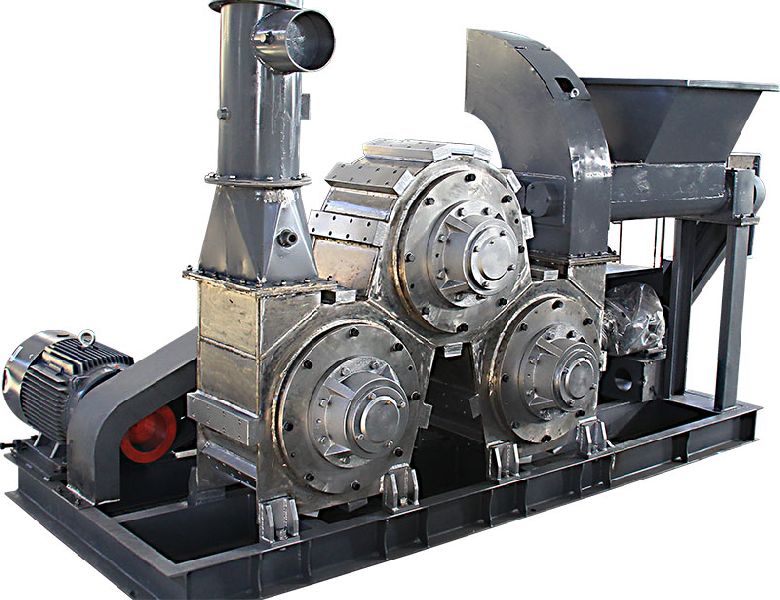

Contact SupplierMineral powder surface modifying machine, also called as Powder surface coating machine, is widely used in the fields of non-metal stuffing like pigment, plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials and dope industries, is an outcome of the development of new and high technology nowadays. After dealing with Powder Coating machine, it can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance binding force of interfaces and rising the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, saving product cost and adding special physical and chemical property to the product to some extent. For resolving the above-mentioned problem in production, this high efficiency equipment CLG powder surface modifying machine is recommended by our company as a result of hard research work.

Advantage

1, Continuous operation, large capacity, suitable for industrialization production in various scale.

2, High use and less consumption of modifying agent. high covering and active index of power, energy saving.

3, Both modifying and dispersion function, suitable for any fine materials, special active effect for material with small proportion and big cubage weight like white carbon, mica powder and talcum powder.

4, Powder and agent mixing and running in high speed and vortex, high modifying efficiency, with little change of granulate shape.

5, Running at vacuum, air tight, no dust leakage, no pollution, good operation condition, low labor intensity.

6, Operating in heat and cold conditions, no additional heating or cooling system required, easy operation.

7, Independent fluid and non-fluid agent adding system for continuous, stable and even operation.

Product introduction

Mineral powder surface modifying machine, also called as Powder surface coating machine, is widely used in the fields of non-metal stuffing like pigment, plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials and dope industries, is an outcome of the development of new and high technology nowadays. After dealing with Powder Coating machine, it can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance binding force of interfaces and rising the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, saving product cost and adding special physical and chemical property to the product to some extent. For resolving the above-mentioned problem in production, this high efficiency equipment CLG powder surface modifying machine is recommended by our company as a result of hard research work.

Working principle

The powder surface treatment is completed mainly by means of three modifying rollers. The dry powder and dosed agent are put into modifying rollers simultaneously. With high speed rotation, the materials and agent is running in the form of fluidizing vortex. The modification is completed with the heat generated by high speed shearing, colliding and friction among the rotor, stator and thePower.

Model

| Main Power | Blower Power | Speed of Shaft | Capacity | Weight | Overall Dimension | |

| CLG-200D | 11kw | 2.2kw | 5700 r.p.m | 40-150kg/h | 1t | 3200*600*2200mm |

| CLG-3/300 | 3-18.5kw | 5.5kw | 4500 r.p.m | 500-1800kg/h | 3t | 5800*1800*5600mm |

| CLG-3/600 | 3-37kw | 15-22kw | 2700 r.p.m | 2000-4000kg/h | 10t | 11200*3100*6200mm |

| CLG-3/900 | 3-75kw | 45kw | 2000r.p.m | 4000-7000kg/h | 20t | 21000*3800*6500mm |