Welcome to Zhengzhou Xinyun Heavy Industry Technology Co.,Ltd

Manufacturer / Exporter / Supplier Of Sand AAC Plant, Sawdust Drying Machine, Sand Dryer, AAC Product, AAC Block Machine, Crusher Machine, Dryer Machine

Welcome to Zhengzhou Xinyun Heavy Industry Technology Co.,Ltd

Manufacturer / Exporter / Supplier Of Sand AAC Plant, Sawdust Drying Machine, Sand Dryer, AAC Product, AAC Block Machine, Crusher Machine, Dryer Machine

We are offering sawdust drying machine. sawdust drying machine is used for disposing a wide variety of materials.it enjoys features of high operation flexibility, good adaptability, large treatment volume. construction of sawdust drying machine entrance inner plate feeder motor supporter and draft fan operation principle of sawdust drying machine 1. Wet materials are sent into silo by belt and bucket conveyor, 2. the material pass through feeding tube into the feed end. The gradient of feeding tube must be greater than the natural angle of materials, so that material can enter into desiccator. 3.the desiccatorsã¢ï¿½ï¿½ cylinder is an oblique rotating drum. Heat-carrier that enters into the dryer from the low-end can form reflux with the material added from the upper end. 4.with the rotating of cylinder, materials are carried to the bottom end by gravity. 5.wet materials obtain heat input of heat carrier to be dried. process flow of sawdust drying machine technology parameter of sawdust drying machine model (m) gradient( ã�â°) rotation speed (r/min) intake temperature power (kw) capacity (t/h) weight (t) 0.6ã��6 3-5 3-8 700 3 1.5 2.9 0.8ã��8 3-5 3-8 700 4 2.0 3.5 0.8ã��10 3-5 3-8 700 4 2.5 4.5 1ã��10 3-5 3-8 700 5.5 3.5 5.6 1.2ã��10 3-5 3-8 700 7.5 5 14.5 1.2ã��12 3-5 3-8 700 11 6 14.8 1.5ã��12 3-5 2-6 800 15 9 17.8 1.8ã��12 3-5 2-6 800 18 12 25 2.2ã��12 3-5 1.5-6 800 18.5 15 33 2.2ã��14 3-5 1.5-6 800 20 15 41 2.2ã��18 3-5 1.5-6 800 22 18 53.8 2.2ã��20 3-5 1.5-6 800 30 20 56

We are offering sand dryer. the hot air dryer is widely used for drying materials with humidity or granulary in industries of mineral dressing , building materials , metallurgy, chemical industry, cement plant etc., such as limestone slag , coal powder, slag, clay stone. working principals of sand dryer 1.it is composed of rotary cylinder, lifting blade, driving device, supporting device, sealing ring. 2.materials is fed at one end and discharged at the other end. In indirecttype dryer, hot gasses move through the the cylinder in direct contact with the material, either with or against the direction of its flow. The cylinder is equipped with flights , which lifts the material and shower it down through the hot gas stream. characteristics of sand dryer (1) dry strength, highly dispersed material in the gas stream, all the particles surface become the effective area. (2) short drying time (3) simple structure, small footprint, easy construction and maintenance. (4) processing capacity, high thermal efficiency. When dry and non-combination of water, the thermal efficiency of up to 60%. main technical parameters of sand dryer : model the diameter (mm) the length (m) slope speed (r/min) power (kw) volume (m3) whs0.6×8-12 600 8-12 3-5 8 4 2.26 whs0.8×10-10 800 10-12 3-5 7.2 4 5.02 whs1.0×10-12 1000 10-12 3-5 6.73 5.5 7.85 1.2×12-18 1200 12-18 3-5 5.8 11-15 13.31 whs1.5×12-18 1500 12-18 3-5 4.8 15-22 21.2 whs1.8×12-18 1800 12-18 3-5 3.2 185-30 48.22 whs2.2×12-22 2200 12-22 3-5 3 22-30 70.43 whs2.8×15-24 2800 15-24 3-5 2.59 30-55 147.8

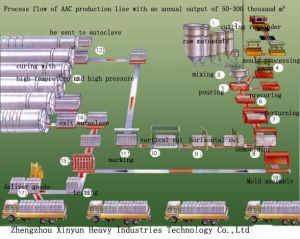

We are offering sand aac plant. we introduce the advanced technology of domestic and international, high pass-rate of production . 1.the introduction of sand aac plant feature of sand aac plant: fly ash autoclave aerated concrete block (sand aac block) is the light and porous building material.it has the advantages of light weight, keeping temperature, heat resistant, fireproof, high intensity, good sound insulation and machinability, conveniently mechanized construction, etc. Size of sand aac plant:sand aac block can be made into many different size of blocks (for example: 600× 200× 100, 600×200× 125, 80× 80× 180, 240× 115× 53, etc), widely used for industry building and common house building.they will completely replace the clay bricks and normal concrete blocks in building construction. 2. Conception of sand aac plant the density of common concrete block is around 1600-2400kg/m3, but fly ash aac block is 500kg/m3, 600kg/m3, 700kg/m3. It has not the big grain, mainly made from silicon material, for example: fly ash, sand, cement, quick lime, gypsum and so on. in brief, there are 5 steps to make fly ash aac block, 1. First, preparing raw material; 2.second, mixing the measured raw material to make slurry and pouring; 3.third, pre-ageing and cutting the green block body; 4. Fourth, grouping the cut block and autoclaving; 5.fifth, packing the autoclaved block and transporting out of plant. sand aac plant suitable materials fly ash, sand, lime, gypsum, cement, water, aluminum powder and aluminum paste 3.sand aac plant production engineering 1. First, dose and match measured raw materials 2. After distributing, feed raw material into pouring mixer to make slurry 3. Through thoroughly mixing, the slurry is poured to mould 4. After pre-curing with a certain temperature & time, the block would reach certain hardness prepare for cutting 5. Tilting hoister would turn over 90 degree of mould 6. Then open the mould & separate it from block, take the block with side plate with cutting cart 7. The block then be cut through the cutter firstly of two vertical sides of block 8. Secondly the horizontal cutting 9. Finally the vertical cutting 10. After cutting, the block is hanged to trolley with side plate by semi-finished product hoister 11. Organizing the cut blocks and put them into autoclave 12. Hardening the blocks under certain temperature and pressure 13. Take finished products out of autoclave 14. The finished product hoister takes the finished product to stock shield 15. Packed for loading 16. The side plate return back by side plate roller 17. Side plate would be organized with open mould 18. Clean the mould and preparing for next pouring 19. Steel bars processing line for slab production.

We are offering aac product. 1.general specification of aac product length: 600mm height: 200mm; 250mm; 300mm width: 60mm; 120mm; 180mm; 240mm(increased gradually by 60) 50mm; 75mm; 100mm; 125mm; 150mm (increased gradually by 25) 1.annual production capacity of production line: 50, 000 m3/year, 100, 000m3/year, 150, 000 m3/year, 200, 000 m3/year, 300, 000 m3/year 2. Drying methods: using boiler and autoclave 3. Raw material: fly ash(or sand), cement, lime, gypsum, aluminum powder paste. the autoclaved aerated concrete block can be produced with different technologies according to differences in quality and category. 2.raw materials of aac block 3.process flow of aac production line we take different technics to produce aac according to the raw material , quality and equipments technical features. Usually, we first grind the sand and slag together some water into slurry, then put some lime , cement , gypsum , foaming agent and foam stabilizer into the slurry, mix them and cast the mixture into the mould . After static foaming and hardening , cut the cake into blocks with the size we want . The cut cakes are then sent into the autoclave , after steam curing , we will get the porous lightweight aac products.

Share your thoughts with other customers for Zhengzhou Xinyun Heavy Industry Technology Co.,Ltd

Add Review