Listing ID #2677195

Company Information

Ask for more detail from the seller

Contact SupplierMilk powder manufacture is a simple process now carried out on a large scale. It involves the gentle removal of water at the lowest possible cost under stringent hygiene conditions while retaining all the desirable natural properties of the milk - colour, flavour, solubility, nutritional value. Whole (full cream) milk contains, typically, about 87% water and skim milk contains about 91% water. During milk powder manufacture, this water is removed by boiling the milk under reduced pressure at low temperature in a process known as evaporation. The resulting concentrated milk is then sprayed in a fine mist into hot air to remove further moisture and so give a powder.

Separation / Standardization : The conventional process for the production of milk powders starts with taking the raw milk received at the dairy factory and pasteurising and separating it into skim milk and cream using a centrifugal cream separator. If WMP is to be manufactured, a portion of the cream is added back to the skim milk to produce a milk with a standardised fat content (typically 26- 30% fat in the powder). Surplus cream is used to make butter or anhydrous milkfat.

Preheating : The next step in the process is "preheating" during which the standardised milk is heated totemperatures between 75 and 120_C and held for a specified time from a few seconds up to several minutes (cf. pasteurisation: 72_C for 15 s). Preheating causes a controlled denaturation of the whey proteins in the milk and it destroys bacteria, inactivates enzymes, generates natural antioxidants and imparts heat stability. The exact heating/holding regime depends on the type of product and its intended end-use. High preheats in WMP are associated with improved keeping quality but reduced solubility. Preheating may be either indirect (via heat exchangers), or direct (via steam injection or infusion into the product), or a mixture of the two. Indirect heaters generally use waste heat from other parts of the process as an energy saving measure.

Evaporation : In the evaporator the preheated milk is concentrated in stages or "effects" from around 9.0% total solids content for skim milk and 13% for whole milk, up to 45-52% total solids. This is achieved by boiling the milk under a vacuum at temperatures below 72_C in a falling film on the inside of vertical tubes, and removing the water as vapour. This vapour, which may be mechanically or thermally compressed, is then used to heat the milk in the next effect of the evaporator which may be operated at a lower pressure and temperature than the preceding effect. Modern plants may have up to seven effects for maximum energy efficiency. More than 85% of the water in the milk may be removed in the evaporator. Evaporators are extremely noisy because of the large quantity of water vapour travelling at very high speeds inside the tubes.

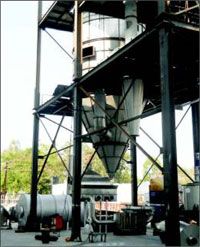

Spray Drying : Spray drying involves atomising the milk concentrate from the evaporator into fine droplets.This is done inside a large drying chamber in a flow of hot air (up to 200_C) using either a spinning disk atomiser or a series of high pressure nozzles. The milk droplets are cooled by evaporation and they never reach the temperature of the air. The concentrate may be heated prior to atomisation to reduce its viscosity and to increase the energy available for drying. Much of the remaining water is evaporated in the drying chamber, leaving a fine powder of around 6% moisture content with a mean particle size typically of < 0.1 mm diameter. Final or "secondary" drying takes place in a fluid bed, or in a series of such beds, in which hot air is blown through a layer of fluidised powder removing water to give product with a moisture content of 2-4%. Precautions must be taken to prevent fires and to vent dust explosions should they occur in the drying chamber or elsewhere. Such explosions can be extremely dangerous to life, property and markets.

Packaging and Storage : Milk powders are immensely more stable than fresh milk but protection from moisture, oxygen, light and heat is needed in order to maintain their quality and shelf life. Milk powders readily take up moisture from the air, leading to a rapid loss of quality and caking or lumping. The fat in WMPs can react with oxygen in the air to give off-flavours, especially at higher storage temperatures (> 30_C) typical of the tropics. Milk powder is packed into either plastic-lined multi-wall bags (25 kg) or bulk bins (_ 600 kg). WMPs are often packed under nitrogen gas to protect the product from oxidation and to maintain their flavour and extend their keeping quality. Packaging is chosen to provide a barrier to moisture, oxygen and light. Bags generally consist of several layers to provide strength and the necessary barrier properties. Shipments of milk powder should never suffer prolonged exposure to direct sunshine especially in tropical countries. A few hours at elevated temperatures (> 40_C) during transshipment can negate many weeks of careful storage. Milk powders of various types are used in a wide range of products including the following.