Listing ID #3935023

Company Information

Ask for more detail from the seller

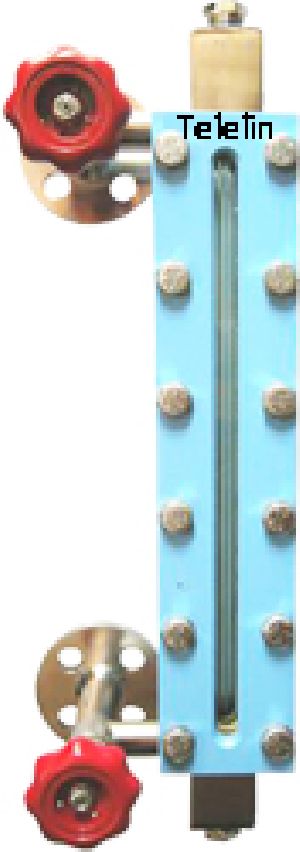

Contact SupplierThese gauges are used for measuring the level in a vessel.These can be used for maximum pressure of upto150kg/cm2 and a maximum temperature of 4000 C. Constructional features include upto 2.5 metre single piece construction with multiple glasses between process connections. A pair of auto shut off ball check valves in standard material of construction; Carbon Steel or Stainless Steel; Polypropylene as optional.

WORKING PRINCIPLEThe principle of Reflex Level Gauges is based on the difference in the refractive indices of liquid and vapour. The liquid column is contained within the recess of the liquid chamber behind the sight glass which is clamped to the gauge body. The sight glass has prismatic right angled grooves on the side facing the liquid and vapor space. Light rays entering from outside the gauge are either absorbed or reflected depending upon whether they enter the liquid or vapour space. When the ray of light encounters the surface of one of the grooves in the vapor space, it is reflected to the opposite surface of the grooves and from there, totally reflected back to the direction of observation. Thus vapour space appears as silvery white. When the light ray encounters the surface of the grooves in the liquid space, it is totally absorbed thereby the liquid behind the glass appear black.

| C/C Distance | : | to100"; single piece liquid chamber. |

| Gauge classification X | : | Low pressure X 30Kg/cm², Medium pressure X 85Kg/cm² Test pressure High pressure X 165Kg/cm², Very high pressure X 210Kg/cm² |

| Gauge glass | : | Tempered soda ash/ Borosilicate (30W x 17mm Thk) / Tempered borosilicate (34W x 17mm Thk) |

| Cushion/Gasket | : | CAF, CNAF, PTFE, SS304 Spiral wound with Graphite Filler & SS316 Spiral wound with Graphite Filler |

| Body (liquid chamber) | : | CS, ASTM A -105, SS304, SS316 or PP (CS Reinforced) |

| Cover plate | : | CS, ASTM A -105, SS304, SS316 or FRP |

| Chamber connection | : | ½" NPT (F) |

| Bolts | : | CS or SS304 or A 193 Gr. B7 |

| Nuts | : | CS or SS304 or A 194 Gr. B4 |

| Gauge connection | : | up (side-side chamber conn) or Straight thru`(top-bottom chamber conn) |

| Process (vessel) conn. | : | Flanged 20 or 25 NB to various standards & pressure ratings Screwed ¾" male shank,union & spherical union |

| Process conn orientation | : | Rear/Rear or Left/Left or Right/Right or Vertical/ Vertical |

| Isolating valves | : | Offset needle valve x auto ball check x Screwed bonnet (85 Kg/cm²) / Union bonnet (165Kg/cm²) / Bolted bonnet (210Kg/cm²) |

| Vent | : | ½" NPT (BSP for PP/TEFLON MOC) plug / valve (Ball, Needle, Diaphragm, Globe, Gate as reqd.) |

| Drain | : | ½" NPT(BSP for PP/TEFLON MOC) plug/valve (Ball, Needle, Diaphragm, Globe, Gate as reqd.) |