Listing ID #1918173

Company Information

Ask for more detail from the seller

Contact SupplierWe are an eminent firm involved in the production of quality Batch Plant. Our entire assortment is manufactured by using the best quality raw material under the supervision of skilled technocrats, as per the international quality standards. Easy to install, these plants excel in performance and require low maintenance. We offer these plants to our esteemed customers in a spectrum of specifications and present them to our patrons at nominal prices. We cater to the bulk requirements of the clients.

Details : Optimization of energy, time, space, and finishing :

Why Statfield's Batch Plant?

Construction :

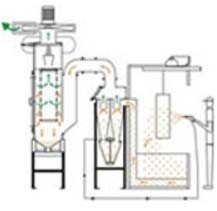

The batch plant mainly comprises of the following :

The basic requirements are the same for powder coating and the liquid painting batch plant.

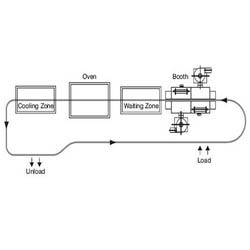

Working :

The working of the batch plant can be explained in the following steps -

The plants can be customized to the requirement of the customer and the dimension of the article.

Oven Selection : Generally electric fired ovens are selected for small batch size i.e. less heat load. For bigger batch size, oil fired or gas fired ovens are recommended. Heat exchanger gives advantage of indirect heating resulting in cleaner process and better curing quality.

| Type | Internal Dim. (mtrs.) | HE K Cal/hr | Blower CMH | Motor HP | Temp °C | Material | Fuel | Batch Load kg | ||

| W | D | H | ||||||||

| Ojas 10 | 1.0 | 2.0 | 1.5 | 45000 | 10000 | 5 | 200 | MS | Diesel or Gas | 500 |

| Ojas 15 | 1.5 | 3.0 | 2.0 | 45000 | 10000 | 5 | 200 | MS | Diesel or Gas | 350 |

| Ojas 20 | 2.0 | 2.5 | 2.0 | 45000 | 10000 | 5 | 200 | MS | Diesel or Gas | 500 |

| Ojas 25 | 2.5 | 4.0 | 2.5 | 65000 | 12000 | 6 | 200 | MS | Diesel or Gas | 700 |

| Type | Internal Dim. (mtrs.) | Heat Load (KW) |

Blower CMH |

Motor HP | Temp °C | Material | Batch Load kg | ||

| W | D | H | |||||||

| Ojas E 20 | 2.0 | 2.0 | 2.0 | 12 | 6000 | 3 | 200 | MS | 200 |

| Ojas E 25 | 2.5 | 2.0 | 2.5 | 36 | 10000 | 5 | 200 | MS | 300 |

| Ojas E 30 | 2.5 | 5.0 | 2.5 | 65 | 10000 | 5 | 200 | MS | 400 |