Listing ID #3856602

Company Information

Ask for more detail from the seller

Contact SupplierMAXTECH Cyclone Dust Collector are intended to accomplish high dust collection efficiencies at low weight drops. We can fulfill the most stringent air contamination control laws and/or item recuperation necessities. We can offer high proficiency Cyclones for particular applications of critical duty condition.

SINGLE, TWIN and QUAD arrangements are accessible as standard configurations. Special arrangements can be supplied to meet your plant formats. Our basic dust containers and outlet plenums are specially crafted to suit every application.

Our range of cyclone is the best solution for some dust collection needs, consolidating high proficiency, low maintenance costs, effortlessness, low pressure drop and well demonstrated bit of equipment. We offer an assortment of arrangements, for example, individual, arrangement and parallel operations relying upon the application.

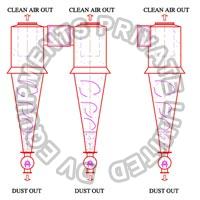

Operating Principle:Dust-laden air enters the tube shaped body of the cyclones tangentially at the top the flow assumes a vortex design as it voyages helically descending. At the point when the particles achieve the divider, grinding gravity compel them to plunge release into a recipient. The centrifugal force from the air tangential velocity causes the heavier dust particles to move profoundly outward toward the cyclone's divider. The cleaned air spirals upward exit at the highest point of the cyclone.

The unit essentially consists of a round and hollow and a cone shaped part. Dust and debris are sucked in at the top. Air containing fine clean extinguishes of the opposite side of the top, while the chips and large dust particles drop out of the base into a drum or a bin. The unit makes utilization of the centrifugal force for the particles' partition. The procedure drives the substantial particles to the base along these lines, making the air lighter to escape from the top. Unit must bay, which gives a stream pivoting development to the gas and subsequently the dust particles are driven towards the conceal surface where they are screwed down.

Cyclone separators are devices that are utilized to particular dust from dust loaded gasses regularly when the dust molecule size is 20 microns or more. Filtration efficiencies in cyclones are not on a par with Bag Filters, however the upkeep expense of cyclones is much lesser than that of Bag Filters.

Cyclones are additionally offered with exceptional wear liners and protections to suit your prerequisites and can be utilized for an extensive variety of uses in the accompanying industries.