Listing ID #4916868

Company Information

Ask for more detail from the seller

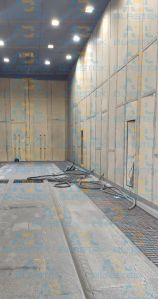

Contact SupplierBlast room equipment is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The surface of the work piece is cleaned by a mixture of abrasive and high pressure compressed air being directed on to the work piece by blast nozzle. The blast room contains the abrasive being shot at the work piece, as well providing lighting and ventilation for the operator's safety.

MEC offer a variety of blast room designs and room configuarations which allow to design a blast room facility uniquely tailored to meet the economic production, safety and environmental concerns of each customer.

The modular blast room is specially ventilated and illuminated for enclosed abrasive blasting, and is fully sealed, dust tight, all steel structure. The components are prefabricated for simple bolt-together erection, with little or no site welding required. The enclosure stands by it's own structural support without connections to the surrounding facilities. The size of the job depends on :-

Optional Accessories:-

Several add-on accessories are available to increase efficiency of Blast Room System. A few are :-

Blasting Media Recovery & Separation System :-

All abrasive recovery systems include three basic functions :-

Mechanical Recovery System :-

Consists of bucket elevator, abrasive cleaner & screw conveyor system

Pneumatic Recovery System :-

Consists of mini hopper, plenum, reclaimer & dust collector

Floor Design :-

The floor design determines the capabilities of the room, degree of labour involvement, cost of purchase & installation. Any of the following can be chosen :-