Listing ID #3877840

Company Information

Ask for more detail from the seller

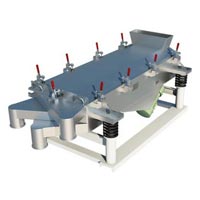

Contact SupplierA high amount of energy is required for sizing or classifying fine cut materials and near cut size grains with high moisture content. This energy can only be provided by the kinetic energy of thethrow. The actual sizing process occurs at the moment of impact of grain on to the screen bottom. In case of humid bulk material, high adhering forces generated between the particles make the grain impossible to pass through the hole in conventional screening method (ie. The so-called Thick Layer Screening).

The high energy required for throw cannot be generated by drop energy. This can be done by raising acceleration to the level of 50g. But this is impossible by moving the whole frame construction. The technique is to move only the screen mat, which is described as a direct excited screen bottom. The machine consists of two sets of moving cross members connected to an inner frame system and an outer frame alternately and both independently to a drive consisting of shaft fitted with eccentric bearings. The alternated frames excite the mat enabling the mat to generate high energy and throw required.

Hence the acceleration and mechanical stress of the frame systems is low but the acceleration of the screen mats is about 40-50g. This multiplies the energy charges to the particle.

During the stretch and relax cycles (8-16 times a second) the opening of polyurethane elastic screen mats gets elongated, thereby, totally eliminating plugging and clogging effect