Listing ID #4346523

Company Information

Ask for more detail from the seller

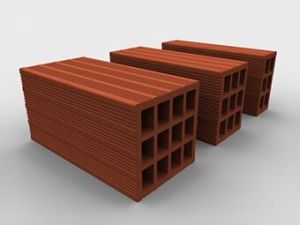

Contact SupplierClay Hollow Bricks & Blocks

These clay hollow blocks are ideal for school, colleges, compound walls and many of the gap filling areas. These bricks are made in rectangular shape and it can withstand all types of natural forces. It is cheap and best suited for quick construction of buildings. Most of the Industries are constructed with clay hollow blocks. These blocks have high tensile strength and more resistant to external environments. These blocks are widely used for building infrastructure and require low maintenance. High dimensional accuracy and consistent finish make these blocks an ideal building material for both load bearing constructions as well as stylish partition walls. These can also be used for wall cladding purposes.

Comparison in Red Clay Bricks (Paul) and Clay Hollow Blocks

| 1) SIZE : 9" X 4" X 3" | 1) SIZE : 12" X 9" X 6" |

| 2) WEIGHT : 2.75 KG. PER PIECE | 2) WEIGHT : 11.5 KG. PER BLOCK |

| 3) 1 Cum2 9" Brick work = 527 Bricks. | 3) 1 Cum2 9" Brick work = 92 Blocks only. |

| 4) Weight of 1 Cm2 Brick work weighs 1.45 Tons. | 4) Weight of 1 Cm2 weighs 1.058 Tons 27 % lighter than clay bricks. |

| 5) Number of mortar quantity required much higher because of number of joints. | 5) Mortar required is much less than clay bricks as 1 block replaced 5.75 Bricks. |

1. Lightweight:

Paul Clay Bricks blocks are around 3 times light weight than regular bricks. It reduces the dead loads on the structure and consequently reduction in the size of foundation, columns and beams in the structure as compared to conventional walling material. Studies have shown reduction in steel up to 15%.

2. High Thermal Insulation:The cellular structure of Paul Brick blocks makes it far better thermal insulator than ordinary bricks. In case of air-conditioning the building A/C load can be reduced as much as 40% approx depending on building design leading to saving in recurring energy cost.

3. Fire Resistance:Paul Clay Bricks is suitable for fire related application.

4. Low Maintenance:Paul Bricks is an inorganic material impervious to rot, insects and other pests. Buildings constructed over sixty five years ago in many different climates have proven it to be the most durable building material available.

5. Environmental Friendly:The manufacturing process creates no by products and uses raw material that are in abundant supply. Manufacturing waste is recycled into the raw material mixing process. Our bricks is recyclable and nontoxic. Fly ash is also a coal waste from thermal power stationes mixed with upto 60% clay and hence the waste is converted into blocks.

6. Fixing:Door and windows frames can be fixed in our blocks masonry by using screws and raw plugs easily.

7. Energy Efficient:The manufacturing process creates millions of tiny air cells which provide excellent thermal resistance. This makes living environment more comfortable in various climate conditions. This leads to saving in electricity.

Sizes available are: