-

Supply Type

Manufacturer, Exporter, Supplier

Preferred Buyer From :

All over the world

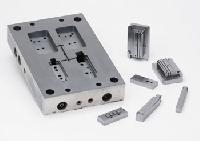

We bring forth a wide range of Plastic Injection Molds which is designed keeping the requirements of the clients in mind. We offer our Plastic Injection Molds in many dimensions and specifications....

View More Details