Listing ID #2406943

Company Information

Ask for more detail from the seller

Contact Supplier

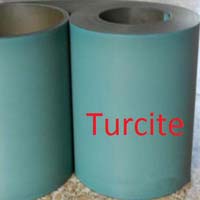

PTFE Sheets are typically of two types, namely Skewed PTFE Sheets and Moulded PTFE Sheets. Widely used in applications where high abrasion resistance is required, chemical resistance, high heat resistance, Oil & Acid resitance, etc.

PTFE is principally used as a gasket material because of it's capability to remain unaffected by the majority of chemicals used in industry. It is also classified, in most cases, as a food grade material, making it acceptable to both medical and food production industries. There are three basic types of PTFE gasket materials. Virgin PTFE , filled PTFE and expanded PTFE .Virgin PTFE is by far the least expensive of the three varieties, and is used in most general applications. Filled PTFE is a gasket material with a virgin PTFE base to which a substance is added during manufacture to improve the sealing characteristics of PTFE . This "filler" usually is glass or graphite particles although ceramics has sometimes been used. The resulting gasket material is strong, yet highly compressible with very good, though not universal, chemical resistance.

Expanded PTFE is virgin PTFE to which a stress resistance has been added by means of molecular rearrangement during manufacture. This process ensures that the molecular chains from which the PTFE is constructed, do not arrange themselves into set patterns. This means that expanded PTFE possesses no structural weakness (grain) and expands and contracts equally in all directions. Because no additives are required, expanded PTFE also possesses the unique chemical resistance of virgin PTFE .

![TEFLON SHEETS [KHAKHRA M/C BELT]](https://img1.exportersindia.com/product_images/bc-small/dir_84/2505071/teflon-sheets-2217244.jpg)